Page 245 - Handbook of Structural Steel Connection Design and Details

P. 245

Welded Joint Design and Production

230 Chapter Three

3.7 Welding Cost Analysis

Welding is a labor-intensive technology. Electricity, equipment depre-

ciation, electrodes, gases, and fluxes constitute a very small portion of

the total welding cost. Therefore, the prime focus of cost control will

be on reducing the amount of time required to make a weld.

The following example is given to illustrate the relative costs of

material and labor, as well as to assess the effects of proper process

selection. The example to be considered is the groove weld of beam

flange-to-column connections. Since this is a multiple-pass weld, the

most appropriate analysis method is to consider the welding cost per

weight of weld metal deposited, such as dollars per pound. Other

analysis methods include cost per piece, ideal for manufacturers asso-

ciated with the production of identical parts on a repetitive basis, and

cost per length, appropriate for single-pass welds of substantial

length. The two welding processes to be considered are shielded metal

arc welding and flux-cored arc welding. Either would generate high-

quality welds when properly used.

To calculate the cost per weight of weld metal deposited, an equa-

tion taking the following format is used:

electrode cost labor overhead rate

Cost per weight

efficiency (deposition rate)(operating factor)

The cost of the electrode is simply the purchase cost of the welding con-

sumable used. Not all of this filler metal is converted directly to deposited

weld metal. There are losses associated with slag, spatter, and in the case

of SMAW, the stub loss (the end portion of the electrode that is discarded).

To account for these differences, an efficiency factor is applied. The follow-

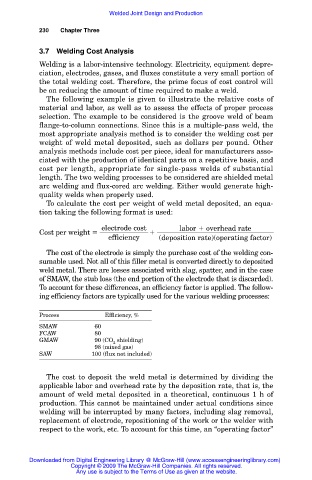

ing efficiency factors are typically used for the various welding processes:

Process Efficiency, %

SMAW 60

FCAW 80

GMAW 90 (CO shielding)

2

98 (mixed gas)

SAW 100 (flux not included)

The cost to deposit the weld metal is determined by dividing the

applicable labor and overhead rate by the deposition rate, that is, the

amount of weld metal deposited in a theoretical, continuous 1 h of

production. This cannot be maintained under actual conditions since

welding will be interrupted by many factors, including slag removal,

replacement of electrode, repositioning of the work or the welder with

respect to the work, etc. To account for this time, an “operating factor”

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.