Page 40 - Handbook of Structural Steel Connection Design and Details

P. 40

Fasteners and Welds for Structural Connections

Fasteners and Welds for Structural Connections 25

Summary. In preparing a weld symbol, insert size, weld-type symbol,

length of weld, and spacing, in that order from left to right. The per-

pendicular leg of the symbol for fillet, bevel, J, and flare-bevel welds

should be on the left of the symbol. Bear in mind also that arrow-side and

otherside welds are the same size unless otherwise noted. When billing

of detail material discloses the identity of the far side with the near side,

the welding shown for the near side also will be duplicated on the far side.

Symbols apply between abrupt changes in direction of welding unless

governed by the all-around symbol or dimensioning shown.

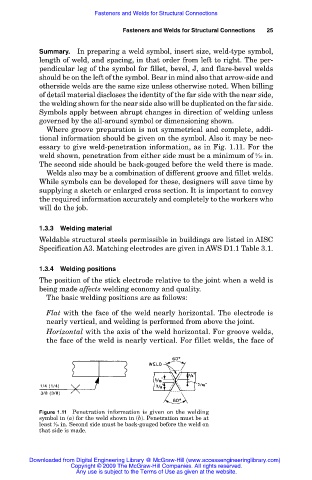

Where groove preparation is not symmetrical and complete, addi-

tional information should be given on the symbol. Also it may be nec-

essary to give weld-penetration information, as in Fig. 1.11. For the

weld shown, penetration from either side must be a minimum of ⁄16 in.

3

The second side should be back-gouged before the weld there is made.

Welds also may be a combination of different groove and fillet welds.

While symbols can be developed for these, designers will save time by

supplying a sketch or enlarged cross section. It is important to convey

the required information accurately and completely to the workers who

will do the job.

1.3.3 Welding material

Weldable structural steels permissible in buildings are listed in AISC

Specification A3. Matching electrodes are given in AWS D1.1 Table 3.1.

1.3.4 Welding positions

The position of the stick electrode relative to the joint when a weld is

being made affects welding economy and quality.

The basic welding positions are as follows:

Flat with the face of the weld nearly horizontal. The electrode is

nearly vertical, and welding is performed from above the joint.

Horizontal with the axis of the weld horizontal. For groove welds,

the face of the weld is nearly vertical. For fillet welds, the face of

Figure 1.11 Penetration information is given on the welding

symbol in (a) for the weld shown in (b). Penetration must be at

3

least ⁄16 in. Second side must be back-gouged before the weld on

that side is made.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.