Page 51 - Handbook of Surface Improvement and Modification

P. 51

46 Gloss Enhancement

3.2 ADDITIVES USED

Wax-based additives

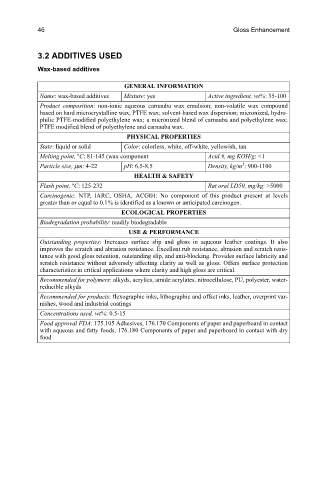

GENERAL INFORMATION

Name: wax-based additives Mixture: yes Active ingredient, wt%: 35-100

Product composition: non-ionic aqueous carnauba wax emulsion; non-volatile wax compound

based on hard microcrystalline wax, PTFE wax; solvent-based wax dispersion; micronized, hydro-

philic PTFE-modified polyethylene wax; a micronized blend of carnauba and polyethylene wax;

PTFE modified blend of polyethylene and carnauba wax.

PHYSICAL PROPERTIES

State: liquid or solid Color: colorless, white, off-white, yellowish, tan

o

Melting point, C: 81-145 (wax component Acid #, mg KOH/g: <1

3

Particle size, μm: 4-22 pH: 6.5-8.5 Density, kg/m : 900-1100

HEALTH & SAFETY

o

Flash point, C: 125-232 Rat oral LD50, mg/kg: >5000

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

ECOLOGICAL PROPERTIES

Biodegradation probability: readily biodegradable

USE & PERFORMANCE

Outstanding properties: Increases surface slip and gloss in aqueous leather coatings. It also

improves the scratch and abrasion resistance. Excellent rub resistance, abrasion and scratch resis-

tance with good gloss retention, outstanding slip, and anti-blocking. Provides surface lubricity and

scratch resistance without adversely affecting clarity as well as gloss. Offers surface protection

characteristics in critical applications where clarity and high gloss are critical.

Recommended for polymers: alkyds, acrylics, amide acrylates, nitrocellulose, PU, polyester, water-

reducible alkyds

Recommended for products: flexographic inks, lithographic and offset inks, leather, overprint var-

nishes, wood and industrial coatings

Concentrations used, wt%: 0.5-15

Food approval FDA: 175.105 Adhesives, 176.170 Components of paper and paperboard in contact

with aqueous and fatty foods, 176.180 Components of paper and paperboard in contact with dry

food