Page 52 - Handbook of Surface Improvement and Modification

P. 52

3.2 Additives used 47

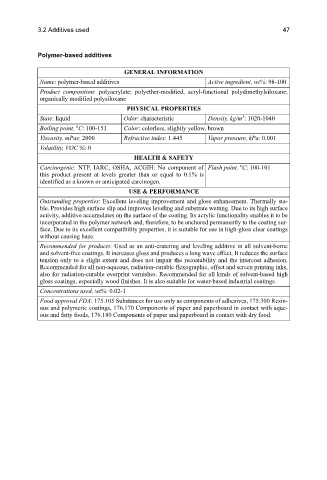

Polymer-based additives

GENERAL INFORMATION

Name: polymer-based additives Active ingredient, wt%: 98-100

Product composition: polyacrylate; polyether-modified, acryl-functional polydimethylsiloxane;

organically modified polysiloxane

PHYSICAL PROPERTIES

3

State: liquid Odor: characteristic Density, kg/m : 1020-1040

o

Boiling point, C: 100-151 Color: colorless, slightly yellow, brown

Viscosity, mPas: 2000 Refractive index: 1.445 Vapor pressure, kPa: 0.001

Volatility, VOC %: 0

HEALTH & SAFETY

o

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of Flash point, C: 100-101

this product present at levels greater than or equal to 0.1% is

identified as a known or anticipated carcinogen.

USE & PERFORMANCE

Outstanding properties: Excellent leveling improvement and gloss enhancement. Thermally sta-

ble. Provides high surface slip and improves leveling and substrate wetting. Due to its high surface

activity, additive accumulates on the surface of the coating. Its acrylic functionality enables it to be

incorporated in the polymer network and, therefore, to be anchored permanently to the coating sur-

face. Due to its excellent compatibility properties, it is suitable for use in high-gloss clear coatings

without causing haze.

Recommended for products: Used as an anti-cratering and leveling additive in all solvent-borne

and solvent-free coatings. It increases gloss and produces a long wave effect. It reduces the surface

tension only to a slight extent and does not impair the recoatability and the intercoat adhesion.

Recommended for all non-aqueous, radiation-curable flexographic, offset and screen printing inks,

also for radiation-curable overprint varnishes. Recommended for all kinds of solvent-based high

gloss coatings, especially wood finishes. It is also suitable for water-based industrial coatings.

Concentrations used, wt%: 0.02-1

Food approval FDA: 175.105 Substances for use only as components of adhesives, 175.300 Resin-

ous and polymeric coatings, 176.170 Components of paper and paperboard in contact with aque-

ous and fatty foods, 176.180 Components of paper and paperboard in contact with dry food.