Page 40 - High Power Laser Handbook

P. 40

12 G a s , C h e m i c a l , a n d F r e e - E l e c t r o n L a s e r s Carbon Dioxide Lasers 13

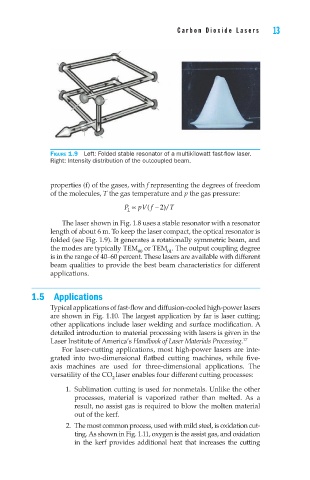

Figure 1.9 Left: Folded stable resonator of a multikilowatt fast-flow laser.

Right: Intensity distribution of the outcoupled beam.

properties (f) of the gases, with f representing the degrees of freedom

of the molecules, T the gas temperature and p the gas pressure:

P ∝ L pVf − ( ) 2/ T

The laser shown in Fig. 1.8 uses a stable resonator with a resonator

length of about 6 m. To keep the laser compact, the optical resonator is

folded (see Fig. 1.9). It generates a rotationally symmetric beam, and

the modes are typically TEM or TEM . The output coupling degree

01

00

is in the range of 40–60 percent. These lasers are available with different

beam qualities to provide the best beam characteristics for different

applications.

1.5 Applications

Typical applications of fast-flow and diffusion-cooled high-power lasers

are shown in Fig. 1.10. The largest application by far is laser cutting;

other applications include laser welding and surface modification. A

detailed introduction to material processing with lasers is given in the

Laser Institute of America’s Handbook of Laser Materials Processing. 17

For laser-cutting applications, most high-power lasers are inte-

grated into two-dimensional flatbed cutting machines, while five-

axis machines are used for three-dimensional applications. The

versatility of the CO laser enables four different cutting processes:

2

1. Sublimation cutting is used for nonmetals. Unlike the other

processes, material is vaporized rather than melted. As a

result, no assist gas is required to blow the molten material

out of the kerf.

2. The most common process, used with mild steel, is oxidation cut-

ting. As shown in Fig. 1.11, oxygen is the assist gas, and oxidation

in the kerf provides additional heat that increases the cutting