Page 476 - High Power Laser Handbook

P. 476

444 Fi b er L a s er s Intr oduction to Optical Fiber Lasers 445

900 20

10

800

0

700

44-µm core diameter −10

A eff (µm 2 ) 600 −20 −20 0 20

500

400 20

27-µm core diameter

300 10

0

200

0 5 10 15 20 25 30 35 40 −10

Bend radius (cm)

−20

(a)

−20 0 20

(b)

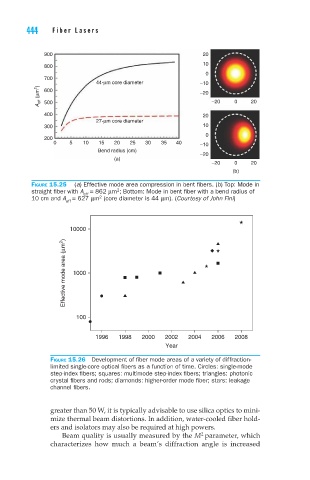

Figure 15.25 (a) Effective mode area compression in bent fibers. (b) Top: Mode in

straight fiber with A = 862 µm ; Bottom: Mode in bent fiber with a bend radius of

2

eff

2

10 cm and A = 627 µm (core diameter is 44 µm). (Courtesy of John Fini)

eff

10000

Effective mode area (µm 2 ) 1000

100

1996 1998 2000 2002 2004 2006 2008

Year

Figure 15.26 Development of fiber mode areas of a variety of diffraction-

limited single-core optical fibers as a function of time. Circles: single-mode

step-index fibers; squares: multimode step-index fibers; triangles: photonic

crystal fibers and rods; diamonds: higher-order mode fiber; stars: leakage

channel fibers.

greater than 50 W, it is typically advisable to use silica optics to mini-

mize thermal beam distortions. In addition, water-cooled fiber hold-

ers and isolators may also be required at high powers.

Beam quality is usually measured by the M parameter, which

2

characterizes how much a beam’s diffraction angle is increased