Page 221 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 221

198 High Tenrprr~turr Solid Oxide Fwl Cells: Fundamentals, Design and Applications

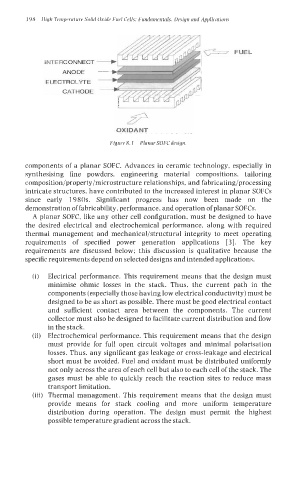

FUEL

I NTE RC ON N E CT

ANODE

ELECTROLYTE

CATHODE

OXIDANT

Figure 8. I Planar SOFC design.

components of a planar SOFC. Advances in ceramic technology, especially in

synthesising fine powders, engineering material compositions, tailoring

composition/property/microstructure relationships, and fabricating/processing

intricate structures, have contributed to the increased interest in planar SOFCs

since early 1980s. Significant progress has now been made on the

demonstration of fabricability, performance, and operation of planar SOFCs.

A planar SOFC, like any other cell configuration, must be designed to have

the desired electrical and electrochemical performance, along with required

thermal management and mechanical/structural integrity to meet operating

requirements of specified power generation applications [3]. The key

requirements are discussed below: this discussion is qualitative because the

specific requirements depend on selected designs and intended applications.

6) Electrical performance. This requirement means that the design must

minimise ohmic losses in the stack. Thus, the current path in the

components (especially those having low electrical conductivity) must be

designed to be as short as possible. There must be good electrical contact

and sufficient contact area between the components. The current

collector must also be designed to facilitate current distribution and flow

in the stack.

(ii) Electrochemical performance. This requirement means that the design

must provide for full open circuit voltages and minimal polarisation

losses. Thus, any significant gas leakage or cross-leakage and electrical

short must be avoided. Fuel and oxidant must be distributed uniformly

not only across the area of each cell but also to each cell of the stack. The

gases must be able to quickly reach the reaction sites to reduce mass

transport limitation.

(iii) Thermal management. This requirement means that the design must

provide means for stack cooling and more uniform temperature

distribution during operation. The design must permit the highest

possible temperature gradient across the stack.