Page 224 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 224

Cell and Stack Designs 201

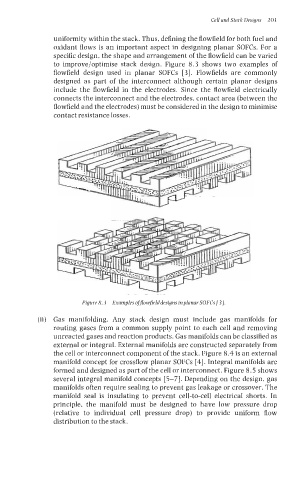

uniformity within the stack. Thus, defining the flowfield for both fuel and

oxidant flows is an important aspect in designing planar SOFCs. For a

specific design, the shape and arrangement of the flowfield can be varied

to improve/optimise stack design. Figure 8.3 shows two examples of

flowfield design used in planar SOFCs [3]. Flowfields are commonly

designed as part of the interconnect although certain planar designs

include the flowfield in the electrodes. Since the flowfield electrically

connects the interconnect and the electrodes, contact area (between the

flowfield and the electrodes) must be considered in the design to minimise

contact resistance losses.

Figure 8.3 Examples offlowfielddesigns inplanar SOFCs [3].

(ii) Gas manifolding. Any stack design must include gas manifolds for

routing gases from a common supply point to each cell and removing

unreacted gases and reaction products. Gas manifolds can be classified as

external or integral. External manifolds are constructed separately from

the cell or interconnect component of the stack. Figure 8.4 is an external

manifold concept for crossflow planar SOFCs [4]. Integral manifolds are

formed and designed as part of the cell or interconnect. Figure 8.5 shows

several integral manifold concepts [S-71. Depending on the design, gas

manifolds often require sealing to prevent gas leakage or crossover. The

manifold seal is insulating to prevent cell-to-cell electrical shorts. In

principle, the manifold must be designed to have low pressure drop

(relative to individual cell pressure drop) to provide uniform flow

distribution to the stack.