Page 225 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 225

202 High Temperature Solid Oxide Fuel Cells: Fundamentals, Design and Applications

FUEL OUT )ANT OUT

FUEL IN

OXIDANT IN

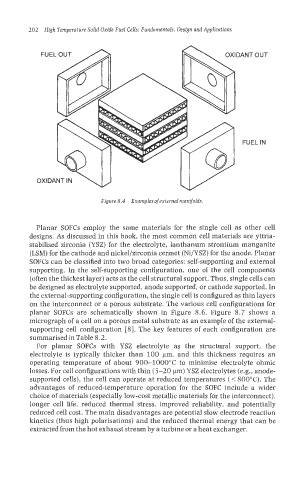

Figure 8.4 Examples of external manifolds.

Planar SOFCs employ the same materials for the single cell as other cell

designs. As discussed in this book, the most common cell materials are yttria-

stabilised zirconia (YSZ) for the electrolyte, lanthanum strontium manganite

(LSM) for the cathode and nickel/zirconia cermet (Ni/YSZ) for the anode. Planar

SOFCs can be classified into two broad categories: self-supporting and external

supporting. In the self-supporting configuration, one of the cell components

(often the thickest layer) acts as the cell structural support. Thus, single cells can

be designed as electrolyte supported, anode supported, or cathode supported. In

the external-supporting configuration, the single cell is configured as thin layers

on the interconnect or a porous substrate. The various cell configurations for

planar SOFCs are schematically shown in Figure 8.6. Figure 8.7 shows a

micrograph of a cell on a porous metal substrate as an example of the external-

supporting cell configuration [SI. The key features of each configuration are

summarised in Table 8.2.

For planar SOFCs with YSZ electrolyte as the structural support, the

electrolyte is typically thicker than 100 pm, and this thickness requires an

operating temperature of about 900-1000°C to minimise electrolyte ohmic

losses. For cell configurations with thin (5-20 pm) YSZ electrolytes (e.g., anode-

supported cells), the cell can operate at reduced temperatures ( < 8OOOC). The

advantages of reduced-temperature operation for the SOFC include a wider

choice of materials (especially low-cost metallic materials for the interconnect),

longer cell life, reduced thermal stress, improved reliability, and potentially

reduced cell cost. The main disadvantages are potential slow electrode reaction

kinetics (thus high polarisations) and the reduced thermal energy that can be

extracted from the hot exhaust stream by a turbine or a heat exchanger.