Page 254 - Hydrocarbon Exploration and Production Second Edition

P. 254

Well Dynamic Behaviour 241

cased hole DST may be considered. Only the interval of interest is perforated and

allowed to flow. All other intervals remain isolated behind casing. Each interval is

sealed off prior to testing another. In both types of DST it is possible to run a

downhole pressure gauge, and therefore to perform a drawdown and build-up survey.

10.5. Tubing Performance

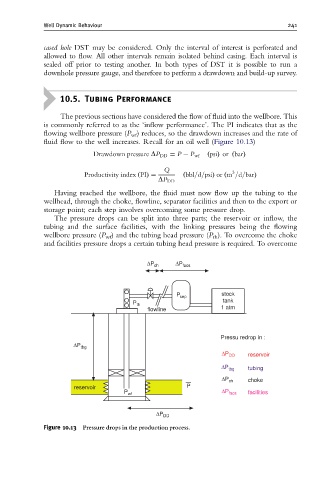

The previous sections have considered the flow of fluid into the wellbore. This

is commonly referred to as the ‘inflow performance’. The PI indicates that as the

flowing wellbore pressure (P wf ) reduces, so the drawdown increases and the rate of

fluid flow to the well increases. Recall for an oil well (Figure 10.13)

Drawdown pressure DP DD ¼ P P wf ðpsiÞ or ðbarÞ

Q

3

Productivity index PIðÞ ¼ ðbbl=d=psiÞ or ðm =d=barÞ

DP DD

Having reached the wellbore, the fluid must now flow up the tubing to the

wellhead, through the choke, flowline, separator facilities and then to the export or

storage point; each step involves overcoming some pressure drop.

The pressure drops can be split into three parts; the reservoir or inflow, the

tubing and the surface facilities, with the linking pressures being the flowing

wellbore pressure (P wf ) and the tubing head pressure (P th ). To overcome the choke

and facilities pressure drops a certain tubing head pressure is required. To overcome

ΔP ch ΔP facs

stock

P sep

P th tank

flowline 1 atm

Pressu redrop in :

ΔP tbg

ΔP DD reservoir

ΔP tbg tubing

ΔP ch choke

reservoir P

P wf ΔP facs facilities

ΔP DD

Figure 10.13 Pressure drops in the production process.