Page 270 - Hydrocarbon Exploration and Production Second Edition

P. 270

Well Dynamic Behaviour 257

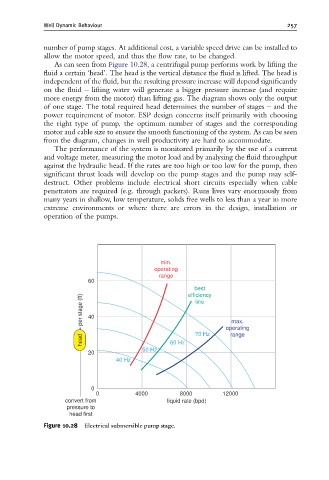

number of pump stages. At additional cost, a variable speed drive can be installed to

allow the motor speed, and thus the flow rate, to be changed.

As can seen from Figure 10.28, a centrifugal pump performs work by lifting the

fluid a certain ‘head’. The head is the vertical distance the fluid is lifted. The head is

independent of the fluid, but the resulting pressure increase will depend significantly

on the fluid – lifting water will generate a bigger pressure increase (and require

more energy from the motor) than lifting gas. The diagram shows only the output

of one stage. The total required head determines the number of stages – and the

power requirement of motor. ESP design concerns itself primarily with choosing

the right type of pump, the optimum number of stages and the corresponding

motor and cable size to ensure the smooth functioning of the system. As can be seen

from the diagram, changes in well productivity are hard to accommodate.

The performance of the system is monitored primarily by the use of a current

and voltage meter, measuring the motor load and by analysing the fluid throughput

against the hydraulic head. If the rates are too high or too low for the pump, then

significant thrust loads will develop on the pump stages and the pump may self-

destruct. Other problems include electrical short circuits especially when cable

penetrators are required (e.g. through packers). Runs lives vary enormously from

many years in shallow, low temperature, solids free wells to less than a year in more

extreme environments or where there are errors in the design, installation or

operation of the pumps.

min.

operating

range

60

best

efficiency

per stage (ft) 40 line

max.

operating

head 60 Hz 70 Hz range

50 Hz

20

40 Hz

0

0 4000 8000 12000

convert from liquid rate (bpd)

pressure to

head first

Figure 10.28 Electrical submersible pump stage.