Page 176 - Improving Machinery Reliability

P. 176

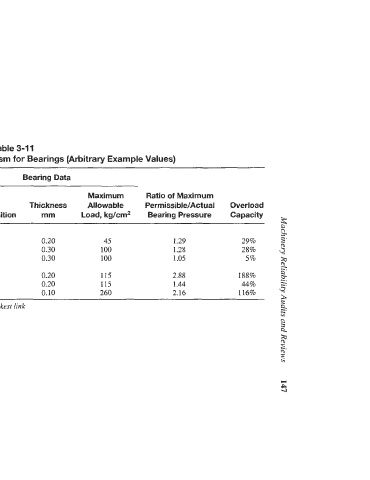

Table 3-1 1

Determination of Design Conservatism for Bearings (Arbitrary Example Values)

Bearing Data

Maximum Ratio of Maximum

Projected Actual Bearing Thickness Allowable Permissible/Actual Overload

Area cm2 Pressure kg/cm2 Composition mm Load, kg/cm2 Bearing Pressure Capacity

3

Vendor X 3

5

Main Bearing 1,900 35 tI 0.20 45 1.29 29% m

Crank Bearing 1,700 78 I1 0.30 100 1.28 28% 9

Crosshead Bearing 1,400 95 I1 0.30 100 1.05 5%

Vendor Y !?

fi'

z

Main Bearing 1,800 40 I1 0.20 115 2.88 188% -

Crank Bearing 1,800 80 I1 0.20 115 1.44 44%

Crosshead Bearing 1,200 120 I 0.10 260 2.16 116%

r:

Resulr: Overload Capacity Vendor X = 5%. Crosshead bearings are the weakest link a. -_

Overload Capacity Vendor Y = 44%. Crank bearings are the weakesr link 2

a

3

a.