Page 395 - Improving Machinery Reliability

P. 395

Startup Responsibilities 359

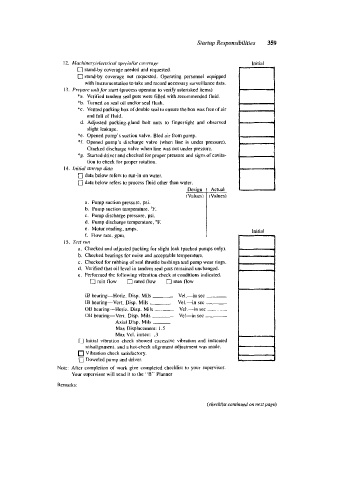

1 2. rtl~iclriirer~/c~Ic.c.lr'ic'crl spcvitilist cowrerge~ Initial

0 stand-by coverage needed and requested.

0 stand-by coverage not requested. Operating personnel equipped

with instrumentation to take and record necessary surveillance data.

13. Pwprrre rtrrit,for torr (prc)cess operator to verify asteriskcd items)

*a. Verified tandem seal pots were filled with recommended fluid.

*b. Turned on seal oil andlor seal flush.

*c. Vented packing box of double seal to ensure the box was free of air

and full of fluid.

d. Adjusted packing-gland bolt nuts to fingertight and observed

slight leakage.

*e. Opened pump's suction valve. Bled air from pump.

*f. Opened pump's discharge valve (when line is under pressure).

Cracked discharge valve when line was not under pressure.

"g. Started driver and checked for proper pressure and signs of cavita-

tion to check for proper rotation.

14. /,ririct/ srorrrip ckrra

0 data below refers lo run-in on water.

0 data below refers to process fluid other than water.

Desim

(Values)

a. Pump suction prcssurc. psi.

b. Pump suction temperature. "F.

c. Pump discharge pressure, psi.

d. Pump discharge temperature. OF.

e. Motor reading. amps. Initial

f. Flow rate. gpm.

15. T~sr riin

a. Checked and adjusted packing for slight leak (packed pumps only).

b. Checked bearings for noise and acceptable temperature.

c. Checked for rubbing of seal throttle bushings and pump wear rings.

d. Verified that oil level in tandem seal pots remained unchanged.

e. Performed the following vibration check at conditions indicated.

Q min flow 0 rated flow 0 max flow

Vel.-in

IB bearing-Horiz. Disp. Mils - sec I__

IB bearing-Vert. Disp. Mils ~ Vel.-in sec ~

OB bearing-Horiz. Disp. Mils ___ Vel.-in sec ___

OB bearing-Vert. Disp. Mils ~ Vel-in sec ____

Axial Disp. Mils __

Max Displacement: I .5

Max Vel. inkc: .3

n Initial vibration check showed excessive vibration and indicated

inisalignment. and a hot-check alignment adjustment was made.

Vibration check satisfactory.

0 Doweled pump and driver.

Note: After complction of work give completed checklibt to your supcrvisor.

Your supervisor will send it to the "B" Planner

Remarks:

(checklist continued on next page)