Page 45 - Improving Machinery Reliability

P. 45

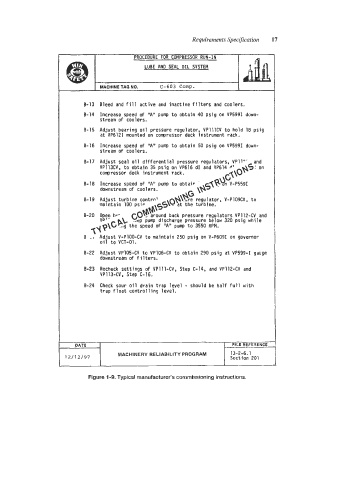

Requirements Specification 17

8-13 Bleed and fill active and inactlve filters and coolers.

8-14 Increase speed of "A" pump to obtain 40 psig on VP599I down-

stream of coolers.

8-15 Adjust bearing oil pressure regulator, VPlllCV to hold 18 psig

at VP612I mounted on conpressor deck instrument rack.

8-16 Increase speed of "A" pump to obtain 50 psig on VP599I down-

stream of coolers.

8-18 Increase speed of "A" pump to obtair

downstream of coolers.

8-19 Adjust turbine control

maintain 100 psi-

B Adjust V-P100-CV to maintain 250 psig on V-P609I on governor

oi 1 to VCT-01.

8-22 Adjust VP105-CV to VPlO6-CV to obtain 290 psig at VP599-I gauge

downstream of filters.

8-23 Recheck settings of VP111-CV, Step C-14, and VP112-CV and

VP113-CY. Step C-16.

5-24 Check sour oil drain trap level - should be half full with

trap float control 1 ing level.

DATE FILE REFERENCE

MACHINERY RELIABILITY PROGRAM 13-2-6.1

12/12/97 Section 201

Figure 1-9. Typical manufacturer's commissioning instructions.