Page 105 - Industrial Cutting of Textile Materials

P. 105

92 Industrial Cutting of Textile Materials

roughly cut components are guided against the vertically moving cutting device

of the band-knife machine (see Section 8.5). Because of its shape and direction of

movement, a band knife can ensure a very high level of accuracy in cutting (see

Sections 7.4.2 and 7.4.3).

After the fusing process, the fused components and their blocks are put back into bun-

dles in the same sequence as they were laid during the spreading process (Section 3.6).

The fine cutting of fused components using the original size pattern pieces is also done by

a band-knife machine that cuts off the fabric allowance remaining after fabric shrinkage.

7.3 Notches and cloth marking drills

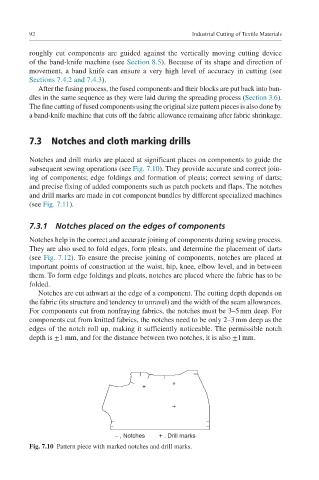

Notches and drill marks are placed at significant places on components to guide the

subsequent sewing operations (see Fig. 7.10). They provide accurate and correct join-

ing of components; edge foldings and formation of pleats; correct sewing of darts;

and precise fixing of added components such as patch pockets and flaps. The notches

and drill marks are made in cut component bundles by different specialized machines

(see Fig. 7.11).

7.3.1 Notches placed on the edges of components

Notches help in the correct and accurate joining of components during sewing process.

They are also used to fold edges, form pleats, and determine the placement of darts

(see Fig. 7.12). To ensure the precise joining of components, notches are placed at

important points of construction at the waist, hip, knee, elbow level, and in between

them. To form edge foldings and pleats, notches are placed where the fabric has to be

folded.

Notches are cut athwart at the edge of a component. The cutting depth depends on

the fabric (its structure and tendency to unravel) and the width of the seam allowances.

For components cut from nonfraying fabrics, the notches must be 3–5 mm deep. For

components cut from knitted fabrics, the notches need to be only 2–3 mm deep as the

edges of the notch roll up, making it sufficiently noticeable. The permissible notch

depth is ±1 mm, and for the distance between two notches, it is also ±1 mm.

– , Notches , Drill marks

Fig. 7.10 Pattern piece with marked notches and drill marks.