Page 166 - Industrial Cutting of Textile Materials

P. 166

Automated laser cutting of textile materials 153

Pump/energy source – High-frequency electric discharge method is used to stim-

ulate the gas mixture. The atoms and molecules of the gas try to follow the changing

polarity of the field, heat up, collide with each other, and get excited.

Optical/reflecting resonator – If the excitation energy has sufficient intensity, the

gas mixture can become a laser. To reach it, the laser beam is reflected back and forth

many times by help of mirrors placed at both ends of the discharge tube. This set of

mirrors is called the optical resonator system. One of the mirrors is completely reflect-

ing, but the other is only partially reflecting to transmit the part of the laser radiation

for further use.

Cooling system – A large quantity of heat generates in the laser tube during the

work process. In order to avoid overheating of critical components and the rise of am-

bient temperature, the heat must be removed from the discharge tube. This is accom-

plished through the use of a special temperature-stabilized air or water cooling system.

10.2.1.2 Cutting head (processing head)

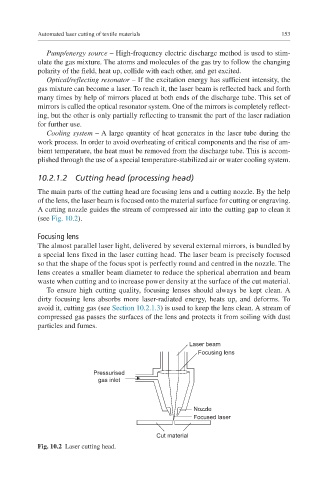

The main parts of the cutting head are focusing lens and a cutting nozzle. By the help

of the lens, the laser beam is focused onto the material surface for cutting or engraving.

A cutting nozzle guides the stream of compressed air into the cutting gap to clean it

(see Fig. 10.2).

Focusing lens

The almost parallel laser light, delivered by several external mirrors, is bundled by

a special lens fixed in the laser cutting head. The laser beam is precisely focused

so that the shape of the focus spot is perfectly round and centred in the nozzle. The

lens creates a smaller beam diameter to reduce the spherical aberration and beam

waste when cutting and to increase power density at the surface of the cut material.

To ensure high cutting quality, focusing lenses should always be kept clean. A

dirty focusing lens absorbs more laser-radiated energy, heats up, and deforms. To

avoid it, cutting gas (see Section 10.2.1.3) is used to keep the lens clean. A stream of

compressed gas passes the surfaces of the lens and protects it from soiling with dust

particles and fumes.

Laser beam

Focusing lens

Pressurised

gas inlet

Nozzle

Focused laser

Cut material

Fig. 10.2 Laser cutting head.