Page 169 - Industrial Cutting of Textile Materials

P. 169

156 Industrial Cutting of Textile Materials

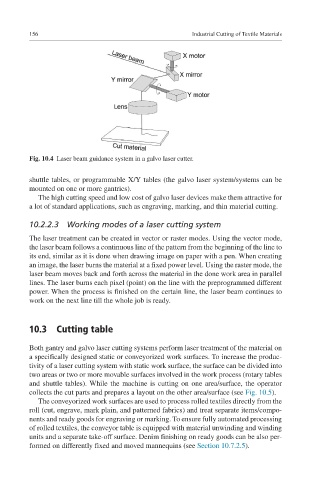

Fig. 10.4 Laser beam guidance system in a galvo laser cutter.

shuttle tables, or programmable X/Y tables (the galvo laser system/systems can be

mounted on one or more gantries).

The high cutting speed and low cost of galvo laser devices make them attractive for

a lot of standard applications, such as engraving, marking, and thin material cutting.

10.2.2.3 Working modes of a laser cutting system

The laser treatment can be created in vector or raster modes. Using the vector mode,

the laser beam follows a continuous line of the pattern from the beginning of the line to

its end, similar as it is done when drawing image on paper with a pen. When creating

an image, the laser burns the material at a fixed power level. Using the raster mode, the

laser beam moves back and forth across the material in the done work area in parallel

lines. The laser burns each pixel (point) on the line with the preprogrammed different

power. When the process is finished on the certain line, the laser beam continues to

work on the next line till the whole job is ready.

10.3 Cutting table

Both gantry and galvo laser cutting systems perform laser treatment of the material on

a specifically designed static or conveyorized work surfaces. To increase the produc-

tivity of a laser cutting system with static work surface, the surface can be divided into

two areas or two or more movable surfaces involved in the work process (rotary tables

and shuttle tables). While the machine is cutting on one area/surface, the operator

collects the cut parts and prepares a layout on the other area/surface (see Fig. 10.5).

The conveyorized work surfaces are used to process rolled textiles directly from the

roll (cut, engrave, mark plain, and patterned fabrics) and treat separate items/compo-

nents and ready goods for engraving or marking. To ensure fully automated processing

of rolled textiles, the conveyor table is equipped with material unwinding and winding

units and a separate take-off surface. Denim finishing on ready goods can be also per-

formed on differently fixed and moved mannequins (see Section 10.7.2.5).