Page 174 - Industrial Cutting of Textile Materials

P. 174

Automated laser cutting of textile materials 161

Using the compressed air as a cutting gas, the beam focus should be located on the

surface of the cut material or in processing thick materials, at the centre of the material

thickness. The focal point has to be positioned accurately on the cut material and its

position kept constant during the whole work process.

The sensitivity to focal position is dependent on the cut material properties. The

sensitivity of focusing is less in high-power lasers than in lower power ones. Smaller

focal points are used to cut material. Large focal points are needed to engrave and

mark material surface.

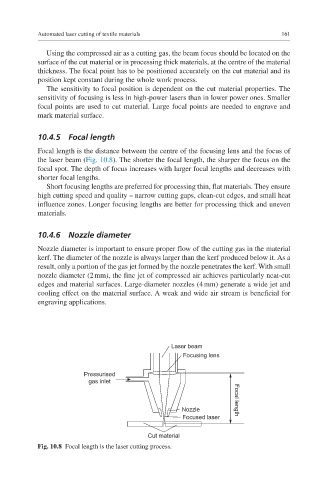

10.4.5 Focal length

Focal length is the distance between the centre of the focusing lens and the focus of

the laser beam (Fig. 10.8). The shorter the focal length, the sharper the focus on the

focal spot. The depth of focus increases with larger focal lengths and decreases with

shorter focal lengths.

Short focusing lengths are preferred for processing thin, flat materials. They ensure

high cutting speed and quality – narrow cutting gaps, clean-cut edges, and small heat

influence zones. Longer focusing lengths are better for processing thick and uneven

materials.

10.4.6 Nozzle diameter

Nozzle diameter is important to ensure proper flow of the cutting gas in the material

kerf. The diameter of the nozzle is always larger than the kerf produced below it. As a

result, only a portion of the gas jet formed by the nozzle penetrates the kerf. With small

nozzle diameter (2 mm), the fine jet of compressed air achieves particularly neat-cut

edges and material surfaces. Large-diameter nozzles (4 mm) generate a wide jet and

cooling effect on the material surface. A weak and wide air stream is beneficial for

engraving applications.

Laser beam

Focusing lens

Pressurised

gas inlet

Nozzle Focal length

Focused laser

Cut material

Fig. 10.8 Focal length is the laser cutting process.