Page 178 - Industrial Cutting of Textile Materials

P. 178

Automated laser cutting of textile materials 165

10.6.3.1 Engraving

During laser engraving, the material surface in certain places is melted and evaporated

by the laser beam. This is known as ‘material removal’. The laser beam physically

removes the part of material surface and creates a cavity on it, noticeable visually and

in touch. The laser engraving process can be done in high speed. Engraving is widely

used in carpet and rug manufacturing, producing garments from textiles with low-cut

pile (see Chapter 18) and fleece. The engraved goods can withstand long wear.

10.6.3.2 Marking

In situations when physical alteration of a material structure is inadmissible, an al-

ternative method is laser marking. During laser marking the laser beam only slightly

alters material properties or appearance. The colour change of the treated material is

the most typical physical effect of this process:

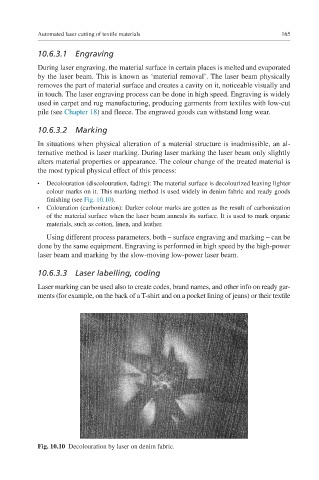

Decolouration (discolouration, fading): The material surface is decolourized leaving lighter

●

colour marks on it. This marking method is used widely in denim fabric and ready goods

finishing (see Fig. 10.10).

Colouration (carbonization): Darker colour marks are gotten as the result of carbonization

●

of the material surface when the laser beam anneals its surface. It is used to mark organic

materials, such as cotton, linen, and leather.

Using different process parameters, both – surface engraving and marking – can be

done by the same equipment. Engraving is performed in high speed by the high-power

laser beam and marking by the slow-moving low-power laser beam.

10.6.3.3 Laser labelling, coding

Laser marking can be used also to create codes, brand names, and other info on ready gar-

ments (for example, on the back of a T-shirt and on a pocket lining of jeans) or their textile

Fig. 10.10 Decolouration by laser on denim fabric.