Page 180 - Industrial Cutting of Textile Materials

P. 180

Automated laser cutting of textile materials 167

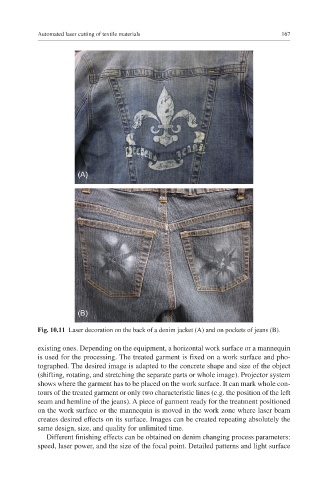

Fig. 10.11 Laser decoration on the back of a denim jacket (A) and on pockets of jeans (B).

existing ones. Depending on the equipment, a horizontal work surface or a mannequin

is used for the processing. The treated garment is fixed on a work surface and pho-

tographed. The desired image is adapted to the concrete shape and size of the object

(shifting, rotating, and stretching the separate parts or whole image). Projector system

shows where the garment has to be placed on the work surface. It can mark whole con-

tours of the treated garment or only two characteristic lines (e.g. the position of the left

seam and hemline of the jeans). A piece of garment ready for the treatment positioned

on the work surface or the mannequin is moved in the work zone where laser beam

creates desired effects on its surface. Images can be created repeating absolutely the

same design, size, and quality for unlimited time.

Different finishing effects can be obtained on denim changing process parameters:

speed, laser power, and the size of the focal point. Detailed patterns and light surface