Page 181 - Industrial Cutting of Textile Materials

P. 181

168 Industrial Cutting of Textile Materials

effects (honeycombs, whiskers, stacks, and train tracks) are created by slowly moving

low-powered laser beam. Different degree surface degradations (e.g. breaking of the

warps of the fabric leaving weft untouched) and even holes (cutting both warp and

weft of the fabric) are created by a high-power laser beam. The advantages comparing

with traditional methods are the following:

It is possible to repeat absolutely the same design/image many times.

●

The process is water and chemical-free, very quick, without health risks to workers, and

●

harmless to environment.

10.7.2 Denim finishing equipment

The laser finishing equipment can be divided in groups depending of the laser power

and work surface used to ensure higher or lower work productivity:

10.7.2.1 Single static surface

A small-size work surface (15 × 15 cm, 25 × 25 cm, and 30 × 30 cm) is used for porta-

ble small-size machines. The machines are suitable to make small designs and logos

on jackets, pockets of jeans, shoes, caps, and others and for making labels and tags for

stores and retail (the shop laser). The laser power is 25–30 W.

10.7.2.2 Static surface in two sections

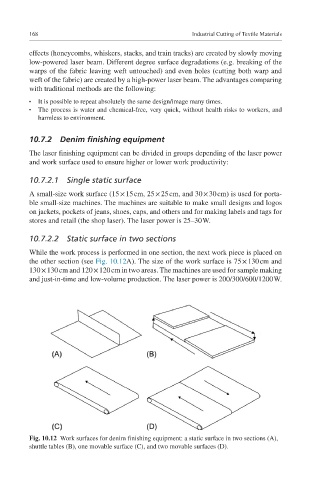

While the work process is performed in one section, the next work piece is placed on

the other section (see Fig. 10.12A). The size of the work surface is 75 × 130 cm and

130 × 130 cm and 120 × 120 cm in two areas. The machines are used for sample making

and just-in-time and low-volume production. The laser power is 200/300/600/1200 W.

Fig. 10.12 Work surfaces for denim finishing equipment: a static surface in two sections (A),

shuttle tables (B), one movable surface (C), and two movable surfaces (D).