Page 172 - Industrial Cutting of Textile Materials

P. 172

Automated laser cutting of textile materials 159

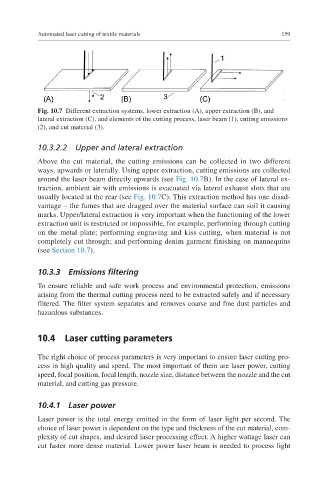

Fig. 10.7 Different extraction systems, lower extraction (A), upper extraction (B), and

lateral extraction (C), and elements of the cutting process, laser beam (1), cutting emissions

(2), and cut material (3).

10.3.2.2 Upper and lateral extraction

Above the cut material, the cutting emissions can be collected in two different

ways, upwards or laterally. Using upper extraction, cutting emissions are collected

around the laser beam directly upwards (see Fig. 10.7B). In the case of lateral ex-

traction, ambient air with emissions is evacuated via lateral exhaust slots that are

usually located at the rear (see Fig. 10.7C). This extraction method has one disad-

vantage – the fumes that are dragged over the material surface can soil it causing

marks. Upper/lateral extraction is very important when the functioning of the lower

extraction unit is restricted or impossible, for example, performing through cutting

on the metal plate; performing engraving and kiss cutting, when material is not

completely cut through; and performing denim garment finishing on mannequins

(see Section 10.7).

10.3.3 Emissions filtering

To ensure reliable and safe work process and environmental protection, emissions

arising from the thermal cutting process need to be extracted safely and if necessary

filtered. The filter system separates and removes coarse and fine dust particles and

hazardous substances.

10.4 Laser cutting parameters

The right choice of process parameters is very important to ensure laser cutting pro-

cess in high quality and speed. The most important of them are laser power, cutting

speed, focal position, focal length, nozzle size, distance between the nozzle and the cut

material, and cutting gas pressure.

10.4.1 Laser power

Laser power is the total energy emitted in the form of laser light per second. The

choice of laser power is dependent on the type and thickness of the cut material, com-

plexity of cut shapes, and desired laser processing effect. A higher wattage laser can

cut faster more dense material. Lower power laser beam is needed to process light