Page 249 - Industrial Cutting of Textile Materials

P. 249

236 Industrial Cutting of Textile Materials

9 7

5 3

1 2

6 4

10 8

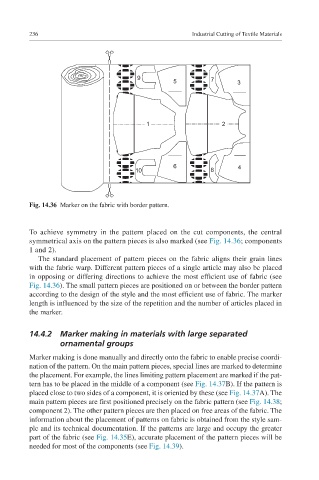

Fig. 14.36 Marker on the fabric with border pattern.

To achieve symmetry in the pattern placed on the cut components, the central

symmetrical axis on the pattern pieces is also marked (see Fig. 14.36; components

1 and 2).

The standard placement of pattern pieces on the fabric aligns their grain lines

with the fabric warp. Different pattern pieces of a single article may also be placed

in opposing or differing directions to achieve the most efficient use of fabric (see

Fig. 14.36). The small pattern pieces are positioned on or between the border pattern

according to the design of the style and the most efficient use of fabric. The marker

length is influenced by the size of the repetition and the number of articles placed in

the marker.

14.4.2 Marker making in materials with large separated

ornamental groups

Marker making is done manually and directly onto the fabric to enable precise coordi-

nation of the pattern. On the main pattern pieces, special lines are marked to determine

the placement. For example, the lines limiting pattern placement are marked if the pat-

tern has to be placed in the middle of a component (see Fig. 14.37B). If the pattern is

placed close to two sides of a component, it is oriented by these (see Fig. 14.37A). The

main pattern pieces are first positioned precisely on the fabric pattern (see Fig. 14.38;

component 2). The other pattern pieces are then placed on free areas of the fabric. The

information about the placement of patterns on fabric is obtained from the style sam-

ple and its technical documentation. If the patterns are large and occupy the greater

part of the fabric (see Fig. 14.35E), accurate placement of the pattern pieces will be

needed for most of the components (see Fig. 14.39).