Page 230 - Industrial Power Engineering and Applications Handbook

P. 230

Transmission of load and suitability of bearings 8/209

with an additional power-transmitting capacity for a speed

ratio of 1.19 = 1.74 kwlbelt.

:. Total load-transmitting capacity = 25.62 kWlbelt

Determine correction factors

(i) For the arc of contact shown in Table 8.7, which is

the same for all manufacturers. Corresponding to an

arc of contact of - D- on the smaller pulley

C

i.e. for 475-400 or 0.077

977.40

The correction factor is not less than 0.99.

(ii) Determine the belt pitch length correction factor form

Arc of (Table 8.6) which is same for all manufacturers.

Corresponding to L = 3330 mm for the belt of section

D, it is 0.87.

Determine the number of belts for the total load to be

transmitted.

Corrected power capacity of each belt of section

D = 25.62 x 0.99 x 0.87

= 22.06 kW

C .

143

:. Number of belts required = -

22.06

= 6.48

or 7 belts

Counter-check the selection for the speed of the smaller

pulley.

Speed = a. d . N, . mmlmin

where N, = speed of the faster shaft = 980 r.p.m.

\ I

\ I d = pitch dia. of the faster (smaller) pulley

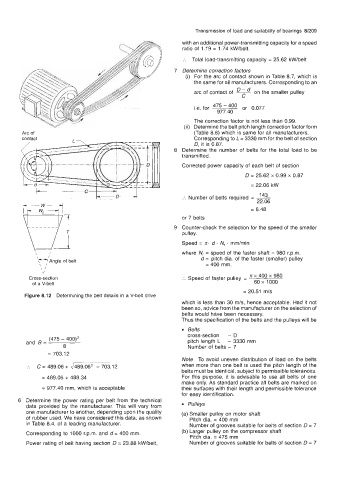

?Angle of belt

\\ I/ = 400 mm.

\I

Cross-section :. Speed of faster pulley = n x 400 x 980

of a V-belt 60 x 1000

= 20.51 mls

Figure 8.12 Determining the belt details in a V-belt drive

which is less than 30 rnls, hence acceptable. Had it not

been so, advice from the manufacturer on the selection of

belts would have been necessary.

Thus the specification of the belts and the pulleys will be

Belts

cross-section - D

(475 - 400)’

and 6= pitch length L - 3330 mm

8 Number of belts - 7

= 703.12

Note To avoid uneven distribution of load on the belts

:. C = 489.06 + J489.06* - 703.12 when more than one belt is used the pitch length of the

belts must be identical, subject to permissible tolerances.

= 489.06 + 488.34 For this purpose, it is advisable to use all belts of one

make only. As standard practice all belts are marked on

= 977.40 mm, which is acceptable their surfaces with their length and permissible tolerance

for easy identification.

6 Determine the power rating per belt from the technical

data provided by the manufacturer. This will vary from Pulleys

one manufacturer to another, depending upon the quality (a) Smaller pulley on motor shaft

of rubber used. We have considered this data, as shown Pitch dia. = 400 mm

in Table 8.4, of a leading manufacturer. Number of grooves suitable for belts of section D = 7

Corresponding to 1000 r.p.m. and d = 400 mm. (b) Larger pulley on the compressor shaft

Pitch dia. = 475 mm

Power rating of belt having section D = 23.88 kWlbelt, Number of grooves suitable for belts of section D = 7