Page 434 - Industrial Power Engineering and Applications Handbook

P. 434

13/408 Industrial Power Engineering and Applications Handbook

process), which a regular production line can ill

afford.

They would require a larger storage area, which

should be dustproof but well ventilated to provide

for sufficient air circulation.

During the drying time, the workpiece may collect

dust from suspended dust particles in the atmosphere.

The air dried surfaces may not be as neat and hard

as the stoved surfaces. Door

6 Stove curing is a rapid method and is obtained by

baking the paint for a specific time in a furnace at a

specific temperature. The temperature and time will

depend upon the type of paint being used and its

thickness, the shape of the workpiece and the

effectiveness of the furnace. (Refer to Table A13.4.)

The oven may be electric or oil-fired convection type,

with an arrangement to circulate the hot air around

the workpiece. The heaters or the furnace may be -

installed at the bottom of the enclosure to cause the

hot air to circulate by natural or forced convection.

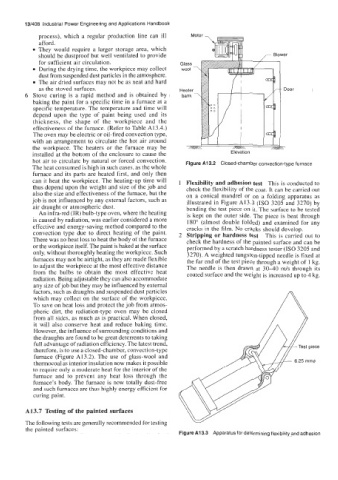

The heat consumed is high in such cases, as the whole Figure A13.2 Closed-chamber convection-type furnace

furnace and its parts are heated first, and only then

can it heat the workpiece. The heating-up time will 1 Flexibility and adhesion test This is conducted to

thus depend upon the weight and size of the job and check the flexibility of the coat. It can be carried out

also the size and effectiveness of the furnace, but the on a conical mandrel or on a folding apparatus as

job is not influenced by any external factors, such as illustrated in Figure A13.3 (IS0 3205 and 3270) by

air draught or atmospheric dust. bending the test piece on it. The surface to be tested

An infra-red (IR) bulb-type oven, where the heating is kept on the outer side. The piece is bent through

is caused by radiation, was earlier considered a more 180" (almost double folded) and examined for any

effective and energy-saving method compared to the cracks in the film. No cracks should develop.

convection type due to direct heating of the paint. 2 Stripping or hardness test This is carried out to

There was no heat loss to heat the body of the furnace check the hardness of the painted surface and can be

or the workpiece itself. The paint is baked at the surface performed by a scratch hardness tester (IS0 3205 and

only, without thoroughly heating the workpiece. Such 3270). A weighted tungsten-tipped needle is fixed at

furnaces may not be airtight, as they are made flexible the far end of the test piece through a weight of 1 kg.

to adjust the workpiece at the most effective distance The needle is then drawn at 30-40 m/s through its

from the bulbs to obtain the most effective heat coated surface and the weight is increased up to 4 kg.

radiation. Being adjustable they can also accommodate

any size of job but they may be influenced by external

factors, such as draughts and suspended dust particles

which may collect on the surface of the workpiece.

To save on heat loss and protect the job from atmos-

pheric dirt, the radiation-type oven may be closed

from all sides, as much as is practical. When closed,

it will also conserve heat and reduce baking time.

However, the influence of surrounding conditions and

the draughts are found to be great deterrents to taking

full advantage of radiation efficiency. The latest trend,

therefore, is to use a closed-chamber, convection-type

furnace (Figure A13.2). The use of glass-wool and

thermocoal as interior insulation now makes it possible

to require only a moderate heat for the interior of the

furnace and to prevent any heat loss through the

furnace's body. The furnace is now totally dust-free

and such furnaces are thus highly energy efficient for

curing paint.

A13.7 Testing of the painted surfaces

The following tests are generally recommended for testing

the painted surfaces:

Figure A13.3 Apparatus for determining flexibility and adhesion