Page 435 - Industrial Power Engineering and Applications Handbook

P. 435

Switchgear and controlgear assemblies 13/409

After the test, the scratch so marked should not show Barrier Salt fumes

up the bare metal surface. Figure A13.4 illustrates the

test arrangement.

A simpler method would be using scratching knives

and making small squares in the surface (minimum

100) around 1 mm2 for primer and 2 mm2 for the

final surface and applying adhesive cellophane tape

25.4 mm wide, with an adhesion strength of 40 k

2.8 g/mm then pulling it off suddenly. Not more than

5% of the squares must peel off.

3 Thickness of coat This can be checked by a magnetic

coating thickness tester gauge (Figure A13.5)

4 Gloss Gloss meters may be used to measure the II Salt solution

specular gloss of the paint.

5 Shade This may be checked visually with the help

of a standard shade card.

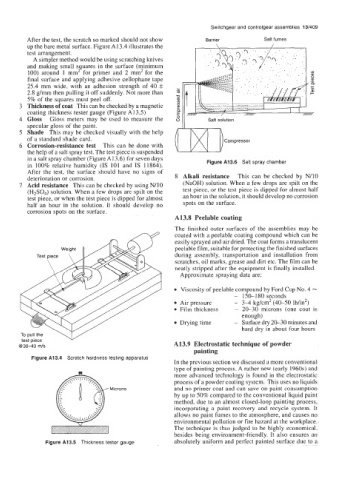

6 Corrosion-resistance test This can be done with

the help of a salt spray test. The test piece is suspended

in a salt spray chamber (FigureA13.6) for seven days

in 100% relative humidity (IS 101 and IS 11864). Figure A13.6 Salt spray chamber

After the test, the surface should have no signs of

deterioration or corrosion. 8 Alkali resistance This can be checked by N/10

7 Acid resistance This can be checked by using N/10 (NaOH) solution. When a few drops are spilt on the

(H2S04) solution. When a few drops are spilt on the test piece, or the test piece is dipped for almost half

test piece, or when the test piece is dipped for almost an hour in the solution, it should develop no corrosion

half an hour in the solution. It should develop no spots on the surface.

corrosion spots on the surface.

A13.8 Peelable coating

The finished outer surfaces of the assemblies may be

coated with a peelable coating compound which can be

easily sprayed and air dried. The coat forms a translucent

peelable film, suitable for protecting the finished surfaces

during assembly, transportation and installation from

scratches, oil marks, grease and dirt etc. The film can be

neatly stripped after the equipment is finally installed.

Approximate spraying data are:

Viscosity of peelable compound by Ford Cup No. 4 =

- 150-180 seconds

Air pressure - 3-4 kg/cm2 (40-50 Ib/in2)

Film thickness - 20-30 microns (one coat is

enough)

Drying time - Surface dry 20-30 minutes and

hard dry in about four hours

w

test piece

CQ30-40 m/s A13.9 Electrostatic technique of powder

painting

Figure A13.4 Scratch hardness testing apparatus

In the previous section we discussed a more conventional

type of painting process. A rather new (early 1960s) and

more advanced technology is found in the electrostatic

process of a powder coating system. This uses no liquids

and no primer coat and can save on paint consumption

by up to 50% compared to the conventional liquid paint

method, due to an almost closed-loop painting process,

incorporating a paint recovery and recycle system. It

allows no paint fumes to the atmosphere, and causes no

environmental pollution or fire hazard at the workplace.

The technique is thus judged to be highly economical,

besides being environment-friendly. It also ensures an

Figure A1 3.5 Thickness tester gauge absolutely uniform and perfect painted surface due to a