Page 438 - Industrial Power Engineering and Applications Handbook

P. 438

13/412 Industrial Power Engineering and Applications Handbook

Blower box

with motor

Connection \ w A

I

-\\ ,e,,\\

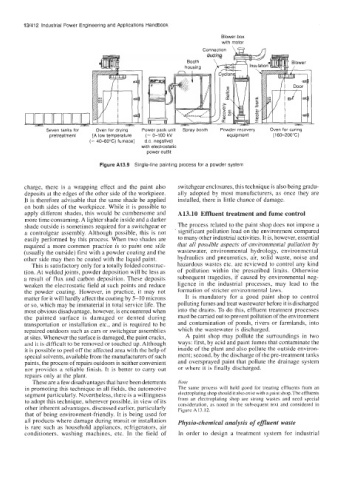

Seven tanks for Oven for drying Power pack unit Spray booth Powder recovery Oven for curing

pretreatment [A low temperature (= 0-1 00 kV equipment (1 60-200°C)

(= 40-60°C) furnace] d.c. negative)

with electrostatic

power outfit

Figure A13.9 Single-line painting process for a powder system

charge, there is a wrapping effect and the paint also switchgear enclosures, this technique is also being gradu-

deposits at the edges of the other side of the workpiece. ally adopted by most manufacturers, as once they are

It is therefore advisable that the same shade be applied installed, there is little chance of damage.

on both sides of the workpiece. While it is possible to

apply different shades, this would be cumbersome and A13.10 EMuent treatment and fume control

more time consuming. A lighter shade inside and a darker

shade outside is sometimes required for a switchgear or The process related to the paint shop does not impose a

a controlgear assembly. Although possible, this is not significant pollution load on the environment compared

easily performed by this process. When two shades are to many other industrial activities. It is, however, essential

required a more common practice is to paint one side that all possible aspects of environmental pollution by

(usually the outside) first with a powder coating and the wastewater, environmental hydrology, environmental

other side may then be coated with the liquid paint. hydraulics and pneumatics, air, solid waste, noise and

This is satisfactory only for a totally folded construc- hazardous wastes etc. are reviewed to control any kind

tion. At welded joints, powder deposition will be less as of pollution within the prescribed limits. Otherwise

a result of flux and carbon deposition. These deposits subsequent tragedies, if caused by environmental neg-

weaken the electrostatic field at such points and reduce ligence in the industrial processes, may lead to the

the powder coating. However, in practice, it may not formation of stricter environmental laws.

matter for it will hardly affect the coating by 5-10 microns It is mandatory for a good paint shop to control

or so, which may be immaterial in total service life. The polluting fumes and treat wastewater before it is discharged

most obvious disadvantage, however, is encountered when into the drains. To do this, effluent treatment processes

the painted surface is damaged or dented during must be carried out to prevent pollution of the environment

transportation or installation etc., and is required to be and contamination of ponds, rivers or farmlands, into

repaired outdoors such as cars or switchgear assemblies which the wastewater is discharged.

at sites. Whenever the surface is damaged, the paint cracks, A paint shop may pollute the surroundings in two

and it is difficult to be removed or touched up. Although ways: first, by acid and paint fumes that contaminate the

it is possible to peel off the affected area with the help of inside of the plant and also pollute the outside environ-

special solvents, available from the manufacturers of such ment; second, by the discharge of the pre-treatment tanks

paints, the process of repairs outdoors is neither convenient and oversprayed paint that pollute the drainage system

nor provides a reliable finish. It is better to carry out or where it is finally discharged.

repairs only at the plant.

These are a few disadvantages that have been deterrents Note

in promoting this technique in all fields, the automotive The same process will hold good for treating effluents from an

segment particularly. Nevertheless, there is a willingness electroplating shop should it also exist with a pain1 bhop. The effluents

to adopt this technique, wherever possible, in view of its from an electroplating shop are strong wastes and need special

consideration, as noted in the subsequent text and considered in

other inherent advantages, discussed earlier, particularly Figure A13.12.

that of being environment-friendly. It is being used for

all products where damage during transit or installation Physio-chemical analysis of effluent waste

is rare such as household appliances, refrigerators, air

conditioners, washing machines, etc. In the field of In order to design a treatment system for industrial