Page 442 - Industrial Power Engineering and Applications Handbook

P. 442

1

13/41 6 Industrial Power Engineering and Applications Handbook

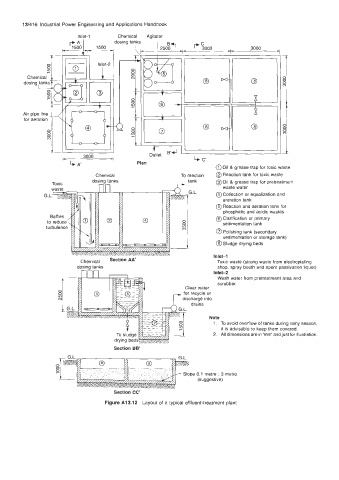

Inlet-1 Chemical Agitator

dosing tanks

+I q5:OlL 1500 -I 3000

0

0 0

0

0

m

0

0

0

0

0

3 m

r

c 3000 4

b A' Plan r" @oil & grease trap for toxic waste

--

Chemical To reaction @ Reaction tank for toxic waste

dosing tanks tank @ 011 & grease trap for pretreatment

Toxic

waste water

@Collection or equalization and

areration tank

0 Reaction and aeration tank for

phosphatic and acidic wastes

@)Clarification or primary

sedimentation tank

@ Polishing tank (secondary

sedimentation or storage tank)

@Sludge drying beds

Inlet-I

Chemical Section Ad' Toxic waste (strong waste from electroplating

dosing tanks shop, spray booth and spent passivation liquor)

Inlet-2

Wash water from pretreatment area and

scrubber.

Clear water

. for recycle or

To avoid overflow of tanks during rainy season,

it is advisable to keep them covered.

All dimensions are in 'mm' and just for illustration.

Section BB

pe 0 1 metre 3 metre

(suggestive)

Section CC'

Figure A13.12 Layout of a typical effluent-treatment plant