Page 441 - Industrial Power Engineering and Applications Handbook

P. 441

Switchgear and controlgear assemblies 13/41 5

promptly drying in an oven. Air-drying paint therefore For level of biological chemical demand (BOD)

must be avoided as far as possible.

BOD is a measure of organic matter present in wastewater

and can be degraded with the help of biomass. The level

Wastewater treatment of BOD, if it exceeds the permissible limits of 30 mgll,

Rapid industrialization has created many problems for will render the wastewater septic and unsafe for use. A

the treatment and disposal of industrial wastes which are higher level of BOD. when detected, can be degraded

mainly responsible for the pollution of rivers. ponds and (neutralized) biologically with the help of biomass (micro-

farmlands, when they are discharged directly, without organism). The biomass consumes and degrades the

proper treatment. organic matter present in the effluent.

The effluents from a paint shop are slightly alkaline Since the discharges of effluents from such a paint

with moderate to weak BOD concentration. They may shop will generally he moderate the required BOD level

also contain traces of heavy metals such as zinc and is automatically maintained without any further treatment.

chromium which, if not trcated. can create environmental Where required, a moderate additional oxygen supply,

and health hazards by harming crops, subsoil drinking for the growth of biomass, can be made available through

water and aquatic tlora and fauna. These effluents must aeration of the wastewater. This can be carried out by

be meticulously treated and neutralized before discharging passing oil-free compressed air through the effluent. The

them into the drains. The method of treatment is simple percolation of effluent dissolves additional oxygen from

and can be performed along the following lines. the atmosphere and helps the growth of bacteria. The

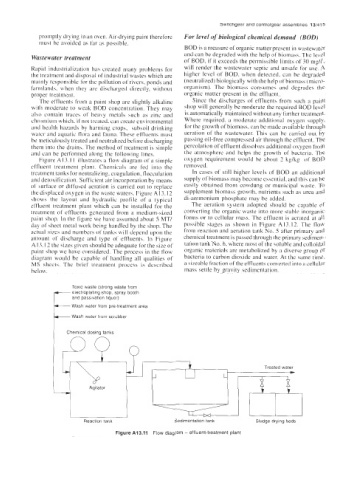

Figure A 13.1 I illustrates a flow diagram of a simple oxygen requirement would be about 2 kg/kg of BOD

eftluent treatment plant. Chemicals are fed into the removed.

treatment tanks for neutralizing. coagulation, flocculation In cases of still higher levels of BOD an additional

and detoxification. Sufficient air incorporation by means supply of biomass may become essential. and this can be

ot surface or diffused aeration is carried out to replace easily obtained from cowdung or municipal waste. To

the displaced oxygen in the waste waters. Figure AI 3.12 supplement biomass growth, nutrients such ac urea and

zhows the layout and hydraulic profile of a typical di-ammonium phosphate may be added.

eftluent treatment plant which can be installed for the The aeration system adopted should be capable of

treatment of effluents generated from a medium-siLed converting the organic waste into more stable inorganic

paint shop. In the figure we have assumed about S MT/ form or to cellular mass. The effluent is aerated at all

day of sheet metal work being handled by the shop. The possible stages as shown in Figure A13.12. The flow

actual sizes and numbers of tanks will depend upon the from reaction and aeration tank No. S after primary and

amount of discharge and type of effluents. In Figure chemical treatment is passed through the primary aedimen-

A 13.12 the sizes given should be adequate for the size of tation tank No. 6, where most of the soluble and colloidal

paint shop we have considered. The process in the flow organic materials are metabolized by n diverse group of

diagram would be capable of handling all qualities of bacteria to carbon dioxide and water. At the same time,

MS sheets. The brief treatment process is described a sizeable fraction ofthe effluents converted into ;I cellular

below. mass settle by gravity sedimentation.

Toxic waste (strong waste from

electroplating shop, spray booth

and passivation liquor)

Wash water from pre-treatment area

Wash water from scrubbet

Chemical dosing tanks

P9 9

Treated water

Y \ ___ *

Agitator

__c

_I

Reaction tank Sedimentation tank Sludge drying beds

Figure A13.11 Flow diagram - effluent-treatment plant