Page 47 - Industrial Power Engineering and Applications Handbook

P. 47

1/28 Industrial Power Engineering and Applications Handbook

frame

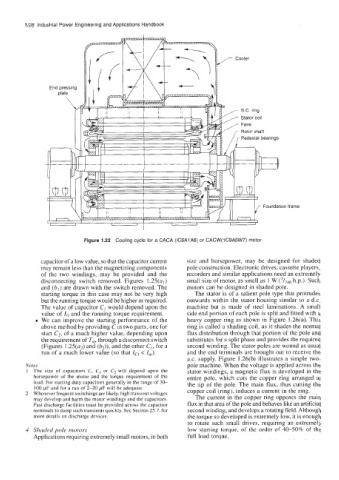

Figure 1.22 Cooling cycle for a CACA (IC6AlA6) or CACW(IC9A6W7) motor

capacitor of a low value, so that the capacitor current size and horsepower, may be designed for shaded

may remain less than the magnetizing components pole construction. Electronic drives, cassette players,

of the two windings, may be provided and the recorders and similar applications need an extremely

disconnecting switch removed. Figures 1.25(Ul) small size of motor, as small as 1 W (1/746 h.p.j. Such

and (b,j are drawn with the switch removed. The motors can he designed in shaded pole.

starting torque in this case may not be very high The stator is of a salient pole type that protrudes

but the running torque would be higher as required. outwards within the stator housing similar to a d.c.

The value of capacitor C1 would depend upon the machine but is made of steel laminations. A small

value of L1 and the running torque requirement. side end portion of each pole is split and fitted with a

We can improve the starting performance of the heavy copper ring as shown in Figure 1.26(a). This

above method by providing C in two parts, one for ring is called a shading coil, as it shades the normal

start Cz, of a much higher value, depending upon flux distribution through that portion of the pole and

the requirement of TFt, through a disconnect switch substitutes for a split phase and provides the required

(Figures 1 .25(u2) and (b2)), and the other C,, for a second winding. The stator poles are wound as usual

run of a much lower value (so that IC, < Zmj. and the end terminals are brought out to receive the

a.c. supply. Figure 1.26(b) illustrates a simple two-

Notes pole machine. When the voltage is applied across the

1 The size of capacitors C, C, or C2 will depend upon the stator windings, a magnetic flux is developed in the

horsepower of the motor and the torque requirement of the entire pole, which cuts the copper ring arranged at

load. For starting duty capacitors generally in the range of 30- the tip of the pole. The main flux, thus cutting the

100 pF and for a run of 2-20 pF will be adequate.

2 Whenever frequent switchings are likely, high transient voltages copper coil (ring), induces a current in the ring.

may develop and harm the motor windings and the capacitors. The current in the copper ring opposes the main

Fast discharge facilities must be provided across the capacitor flux in that area of the pole and behaves like an artificial

terminals to damp such transients quickly. See Section 25.7, for second winding, and develops a rotating field. Although

more details on discharge devices. the torque so developed is extremely low, it is enough

to rotate such small drives, requiring an extremely

4 Shaded pole motors low starting torque, of the order of 40-50% of the

Applications requiring extremely small motors, in both full load torque.