Page 48 - Industrial Power Engineering and Applications Handbook

P. 48

Theory, performance and constructional features of induction motors 1/29

0- Vr(1-4) -0

Centrifugal switch

Main

Im winding opens here

Disconnect

switch

t

Start hnding

XL > XL,

R 3

Note Phase shift is obtained by increasing - P

XL1 COT,

(a) Schematic diagram

Tsi

I

Speed Nr ---+ 7585% N,

(d) Speed-torque characteristics of a split phase motor

1 ; "1 I,",.

StartYwinding

(b) General arrangement

b ..

shift

..

lr

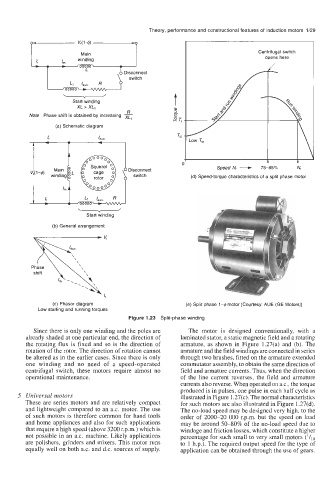

(c) Phasor diagram (e) Split phase 1-4 motor [Courtesy: AUE (GE Motors)]

Low starting and running torques

Figure 1.23 Split-phase winding

Since there is only one winding and the poles are The motor is designed conventionally, with a

already shaded at one particular end, the direction of laminated stator, a static magnetic field and a rotating

the rotating flux is fixed and so is the direction of armature, as shown in Figure 1.27(a) and (b). The

rotation of the rotor. The direction of rotation cannot armature and the field windings are connected in series

be altered as in the earlier cases. Since there is only through two brushes, fitted on the armature extended

one winding and no need of a speed-operated commutator assembly, to obtain the same direction of

centrifugal switch, these motors require almost no field and armature currents. Thus, when the direction

operational maintenance. of the line current reverses, the field and armature

currents also reverse. When operated on a.c., the torque

produced is in pulses, one pulse in each half cycle as

5 Universal motors illustrated in Figure 1.27(c). The normal characteristics

These are series motors and are relatively compact for such motors are also illustrated in Figure 1.27(d).

and lightweight compared to an a.c. motor. The use The no-load speed may be designed very high, to the

of such motors is therefore common for hand tools order of 2000-20 000 r.p.m. but the speed on load

and home appliances and also for such applications may be around 50-80% of the no-load speed due to

that require a high speed (above 3200 r.p.m) which is windage and friction losses, which constitute a higher

not possible in an a.c. machine. Likely applications percentage for such small to very small motors (l/lo

are polishers, grinders and mixers. This motor runs to 1 h.p.). The required output speed for the type of

equally well on both a.c. and d.c. sources of supply. application can be obtained through the use of gears.