Page 570 - Industrial Power Engineering and Applications Handbook

P. 570

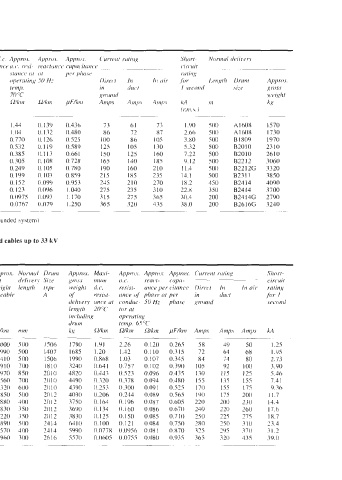

Table A16.7 Armoured three-core power cables 6.35/11 kV (grounded system)a

No. nf i’ures Conductiir Thickness Thicknrr Armuurit~,q Thickntw Apprur.

und crow (AI) of PVC of’r.ommon flu/ wire of PVC‘ (I (1.

.\l~cti~Jliul niinimurn rtirulotrnri covering .\i:e outer

urt’t’u mi. of wire.\ (nom.) minimum shvutlr

n~ricpprd (inin,)

No x mm2 111111 111111 (mm! mm ?11131

-~ _ _ ~

~ ~ ~

~~

3x25 rdv 6 4.2 0.5 4 oxn.8 1.72 46 2470 1.20 1.44 0.139 0.436 73 61 73 1.90 500 A160X 1570

3x35 rdv 6 42 0.5 3.0x0.8 1.8X 49 2800 O.XhX I 04 0.132 0.4xn 86 72 87 2.66 500 A160X 1730

3x50 rdv 6 4.2 0.5 4.Ox0.8 1.88 51 3060 0.641 0.770 0.126 0.525 IO0 86 I 05 3.80 500 ~1x09 1970

3x70 rdv 12 4.2 0.5 4.0x0.8 2.04 55 3560 0.443 0.532 0.119 0.589 125 Ill5 130 5.32 500 ~2nic 2110

3x95 rmiv IS 4.2 0.6 4.0~0.8 2.20 60 4160 0.320 0.385 0.113 0.661 150 125 160 7.22 son 82010 2610

3x120 mm/v IS 4.2 0.6 4.oxn.x 2.20 64 4710 0.253 0.305 0.108 0.728 165 140 185 9 12 son 82212 71l60

3x150 rm/v 15 4.2 0.6 4.0x0.8 2 36 67 5230 0.206 0.249 0.105 0.7~0 191) 160 210 1 1.4 500 B2212G 1320

3x185 rndv 30 4.2 0.7 4.Ox0.8 2.52 72 6090 0.164 0.19~ n.in3 0.859 215 1x5 235 14.1 500 B2111 1850

3x240 rdv 30 4.2 0.7 4.0xn.x 2.68 78 7170 0.125 0.152 0.099 0.953 245 210 270 18.2 450 82414 4090

3x300 rm/v 30 4.2 0.7 4.OxO.8 2.68 83 8120 0.100 0.123 0.096 1.040 27s 235 310 22.8 350 82414 3700

3x400 rmlv 53 4.2 0.7 4.0x0.8 3.00 92 9670 0.0778 o.0975 0.093 1.170 315 275 165 30.4 200 B2414G 2190

3x500 nn/v 51 4.2 0.7 4.0~0.8 3.00 99 I1380 n.n6os 0.0767 0.079 1.250 365 320 435 38.0 200 B2616G 1240

- - -~

_____~ ~ ~ ~~~ ~~ ~~~ ~ ~~~~ ~ ~~ ~ ~

Tables of 6.3511 I kV giade (grounded system) arc also considered suitable for use on 6 6/66 kV (ungrounded system)

Coirrteq: CCI

I1 Paper insulated cables up to 33 kV

Table A16.8 6.35111 kV (Grounded system) paper insulated belted cables (18:692)

~~ ~ ~~ ~~ ~ ~ ~~ ~

Conductor (aluminium) Thickness of Lead sheath Armouring Apprm. Approx. Normul Drum Approx. Ma.ri- Apprm Apprrix. Approu. Currenr mting Short-

~~~ ~ in.culution - ~~ ~~ ~~ ~~~ fiver net delivery Size gro.u mum 1i.c. react- capa- ~~ ~ ~ circuit

Number CroJJ- Confi- Mini- ~ Thick- Appror. Thid- Appro.r. all diu. weight length type weixht d.c. resist- uncc per citance Direct In In air rating

of srctiona1,~uration mum Cund/ Cond/ ees\ dim ness of diu. of cable A of resi.\t- uncc .f phaye uf per in ducr ,fur I

cures ureu no. oj uind. yheath over each over delrvep unce ut condirc- SO Hz phase gruund ,econd

wfri’\ (nom. I (nom j (nom.) armour- tape armour- Imgrh 20°C tor ar

ing 1nom.j ing including operating

(num) (nom.) drum temp. 6S0C

1171i12 m m mm mm mm kgkm nim kg fNm n/km IZhni pF/ktii Amps Ampx Amps kA

__~ __ -~ ____~

1 16 RM 7 5.3 3.8 I .5 27 0.5 32 38 3000 500 I506 1790 1.91 2.26 0.120 0.265 58 49 so 1.25

3 25 SM 6 53 3.8 I .5 26 0.5 31 37 2990 500 1407 1685 1.20 1.42 0.110 0.315 72 64 68 1.95

3 35 SM h 5.3 3.8 I6 29 0.5 34 39 3410 son I506 1990 0.X6X 1.03 0.107 0.345 x4 74 80 2.73

3 50 SM 6 5.3 3.X 17 31 0.5 36 42 3910 700 1x10 3240 0.641 0.757 0.102 0.390 I 05 92 100 3.90

3 70 SM I2 5.3 3.X I .x 34 0.X 40 37 4Y 70 850 2010 4820 0.443 0.523 0.096 0.435 I30 115 125 5.46

3 95 SM 15 5.3 3.8 I .x 37 0.x 43 50 460 700 201 0 4490 0320 0.378 0.094 0.4x0 155 135 155 7.41

3 I20 SM 15 5.1 38 2.0 3 9 0.8 46 52 6320 600 20 10 4390 0.253 0.3oo 0.091 0 52s I70 155 175 9 36

-3 I50 SM 15 5.3 38 2.0 42 0.X 4X 54 6850 son 2012 4030 0.206 0.244 0.08’9 0.565 I90 I75 200 I I .7

3 I85 SM 30 5.3 38 2.1 46 0.8 52 59 7880 400 2012 3750 0 I64 0.196 0.087 0.605 220 200 230 14.4

3 225 SM 30 5.3 38 2.2 49 0.8 55 62 8830 350 2012 3690 0.134 0.160 0.086 0.670 240 220 260 17.6

3 240 SM 30 5.1 3.8 2.3 49 0.8 56 63 9220 350 2012 3830 0.125 0.150 0.085 0.710 250 225 275 18.7

3 300 TM 30 5.3 38 2.4 56 0.8 62 6’9 1 OR90 500 2414 6411) 0.100 0.121 0.084 0.750 2x0 250 310 23.4

3 400 SM 53 53 3.X 2.6 00 0.8 66 73 I 2570 400 2314 5990 0.077~ 0.0’956 ll.081 0.x70 125 2‘95 370 31 2

3 500 SM 53 5.3 3.8 2.X 60 OX 72 XO I4960 300 2616 5570 0.0605 0.07s~ o.080 0.935 365 320 435 39.0

-~ -

~ ~ ~ .. ~~ ~ ~~

~~ ~ ~~ ~

Note Thickness of lapped hcdding approx. 1.5 mni. Thickneys of lappcd serving approx. 2 0 mm

Courtav. CCI