Page 571 - Industrial Power Engineering and Applications Handbook

P. 571

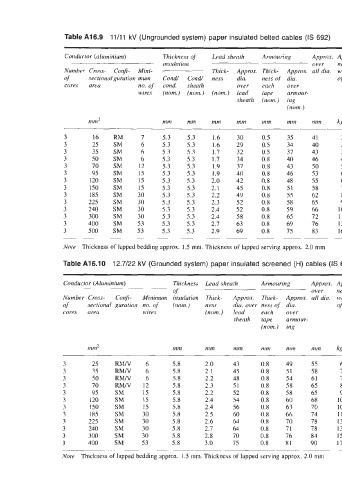

Table A16.9 11/11 kV (Ungrounded system) paper insulated belted cables (IS 692)

Conductor (aluminium) Thickness os Lead sheath Armouring Approx. Appros. Normal Drum Approx. Muxi- Approx. Approx. Approx. Current rating Short-

insulation ____- over net delivery Size gross mum a.c. react- capa- circuit

Number Cross- Confi- Mini- ____ Thick- Approx. Thick- Appros all diu. weight length lype weight ax. resist- ance citance Direct In In air rating

of sectionalgurution mum Cond/ ConaY ness diu. ness of diu, of cable A of resist- ance of per per in duct for 1

cores area no. of cond. sheath over each over delivery airce at conduc- phase at phase ground second

wires (nom.) (nom.) (nom.) lead tape armour- length 20°C tor at 50 Hz

sheath (nom.) ing includ- operating

[nom.) ing temp.

drum 6.5 "C

mm2 mm mm mm mm mm mm mm kg/km mm kg n/km Wkm Nkm pF/km Amps Amps Amps !iA

3 16 RM 7 5.3 5.3 1.6 30 0.5 35 41 3510 500 1506 2040 1.91 2.26 0.120 0.245 58 49 50 1.25

3 25 SM 6 5.3 5.3 1.6 29 0.5 34 40 3490 500 1506 2030 1.20 1.42 0.110 0.275 72 64 68 1.95

3 35 SM 6 5.3 5.3 1.7 32 0.5 37 43 3940 500 1608 2300 0.868 1.03 0.107 0.300 84 74 80 2.73

3 50 SM 6 5.3 5.3 1.7 34 0.8 40 46 4750 850 2010 4630 0.641 0.757 0.102 0.340 105 92 100 3.90

3 70 SM 12 5.3 5.3 1.9 37 0.8 43 50 5600 700 2010 4520 0.443 0.523 0.096 0.385 130 I 15 125 5.46

3 95 SM 15 5.3 5.3 1.9 40 0.8 46 53 6220 550 2010 4020 0.320 0.378 0.094 0.420 155 135 155 7.41

3 120 SM 15 5.3 5.3 2.0 42 0.8 48 55 6860 500 2212 4210 0.253 0.300 0.091 0.460 170 155 175 9.36

3 150 SM 15 5.3 5.3 2.1 45 0.8 51 58 7570 350 2012 3250 0.206 0.244 0.089 0.500 190 175 200 11.7

3 185 SM 30 5.3 5.3 2.2 49 0.8 55 62 8660 350 2012 3630 0.164 0.196 0.087 0.535 220 200 230 14.4

3 225 SM 30 5.3 5.3 2.3 52 0.8 58 65 9640 300 2216 3730 0.134 0.160 0.086 0.600 240 220 260 17.6

3 240 SM 30 5.3 5.3 2.4 52 0.8 59 66 10050 550 2414 6490 0.125 0.150 0.085 0.635 250 225 275 18.7

3 300 SM 30 5.3 5.3 2.4 58 0.8 65 72 11570 400 2414 5590 0.100 0.121 0.084 0.665 280 250 310 23.4

3 400 SM 53 5.3 5.3 2.7 63 0.8 69 76 13520 350 2616 5810 0.0778 0.0956 0.081 0.775 325 295 370 31.2

3 500 SM 53 5.3 5.3 2.9 69 0.8 75 83 16000 250 2616 5080 0.0605 0.0755 0.080 0.825 365 320 435 39.0

- ~~ ~ -~

Note Thickness of lapped bedding approx. 1.5 mm. Thickness of lapped serving approx. 2.0 mm

Table A16.10 12.7/22 kV (Grounded system) paper insulated screened (H) cables (IS 692)

Conductor (Aluminium) Thickness Lead sheath A rmouring Approx. Approx. Normal Drum Approx. Maxi- Approx. Approx. Approx. Current rating Short-

of over net deliver)' size gross mum a.c. react- capa- circuit

Number Cross- Confi- Minimum insulation Thick- Approx. Thick- Approx. all diu. weight length type weight d.c. resist- ance per citance Direct In In air rating

of sectional guration no. of (nom.) ness dio. over ness of diu. of cable A of resist- ance of phase at per in duct for I

cores area wires (nom.) lead each over delivery ance at conduc- S0Hz phase ground second

sheath tape armour- length 20°C tor at

(nom.) ing including operating

drum temp.

65°C

mm2 mm mm mm mm mm mm kg/km mm kg Nkm R/km Wkm pF/km Amps Amps Amps kA

~~

3 25 RMN 6 5.8 2.0 43 0.8 49 55 6520 500 2212 4040 1.20 1.42 0.147 0.216 72 66 72 1.95

3 35 RMN 6 5.8 2.1 45 0.8 51 58 7 190 350 2012 3120 0.868 1.03 0.139 0.239 88 79 88 2.73

3 50 RMN 6 5.8 2.2 48 0.8 54 61 7900 350 2012 3370 0.64 1 0.757 0.132 0.265 105 97 105 3.90

3 70 RWV 12 5.8 2.3 51 0.8 58 65 8900 300 2216 35 10 0.443 0.523 0.125 0.296 I30 120 130 5.46

3 95 SM 15 5.8 2.2 52 0.8 58 65 9030 300 2216 3550 0.320 0.378 0.1 I6 0.355 155 140 160 7.41

3 I20 SM 15 5.8 2.4 54 0.8 60 68 10030 500 2414 5980 0.253 0.300 0.112 0.387 170 I55 180 9.36

3 1 50 SM 15 5.8 2.4 56 0.x 63 7 0 10670 450 2414 5760 0.206 0.244 0.108 0.419 I90 I75 2 IO 11.7

3 I85 SM 30 5.8 2.5 60 0.8 66 74 11910 350 2616 5250 0.164 0.195 0.105 0.456 220 205 245 14.4

3 225 SM 30 5.8 2.6 64 0.8 70 78 13130 300 2616 5020 0.134 0.159 0. I02 0.496 240 22s 275 17.6

3 240 SM 30 5.x 2.7 64 0.8 71 78 13610 300 2616 5160 0. I25 0.149 0.101 0.510 250 230 285 18.7

3 300 SM 30 5.8 2.8 70 0.8 76 84 15430 250 2616 4940 0.100 0.120 0.098 0.557 275 255 320 23.4

3 400 SM 53 5.8 3.0 75 0.8 81 90 17750 200 28 18s 4910 0.0778 0.0941 0.095 0.617 310 285 380 31.2

-~ ~

Note Thickness of lapped bedding approx. 1.5 mm. Thickness of lapped serving approx. 2.0 mm