Page 302 - Industrial Process Plant Construction Estimating and Man Hour Analysis

P. 302

Appendix F

Boiler man-hour tables

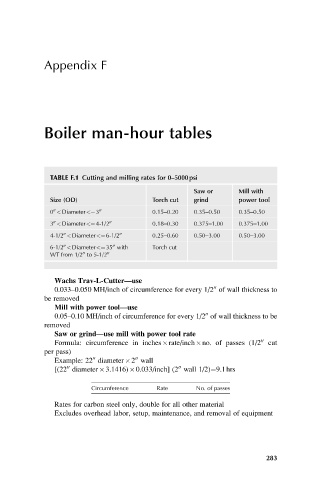

TABLE F.1 Cutting and milling rates for 0–5000psi

Saw or Mill with

Size (OD) Torch cut grind power tool

0 <Diameter<¼3 00 0.15–0.20 0.35–0.50 0.35–0.50

00

3 <Diameter<¼4-1/2 00 0.18–0.30 0.375–1.00 0.375–1.00

00

4-1/2 <Diameter<¼6-1/2 00 0.25–0.60 0.50–3.00 0.50–3.00

00

6-1/2 <Diameter<¼35 with Torch cut

00

00

WT from 1/2 to 5-1/2 00

00

Wachs Trav-L-Cutter—use

0.033–0.050 MH/inch of circumference for every 1/2 of wall thickness to

00

be removed

Mill with power tool—use

0.05–0.10 MH/inch of circumference for every 1/2 of wall thickness to be

00

removed

Saw or grind—use mill with power tool rate

Formula: circumference in inches rate/inch no. of passes (1/2 cut

00

per pass)

Example: 22 diameter 2 wall

00

00

[(22 diameter 3.1416) 0.033/inch] (2 wall 1/2)¼9.1hrs

00

00

Circumference Rate No. of passes

Rates for carbon steel only, double for all other material

Excludes overhead labor, setup, maintenance, and removal of equipment

283