Page 282 - Industrial Wastewater Treatment, Recycling and Reuse

P. 282

256 Industrial Wastewater Treatment, Recycling, and Reuse

substrates based on the substrate H 2 , production varied (Cusick et al., 2010;

Lenin Babu et al., 2013a,b; Lu et al., 2010; Selembo et al., 2009; Venkata

Mohan and Lenin Babu, 2011; Wagner et al., 2009). Integrating the two

processes showed good improvement in the treatment as well as in the addi-

tional product recovery (Lenin Babu et al., 2013a; Tuna et al., 2009; Wang

et al., 2011). Nevertheless, a number of challenges still exist that need to be

addressed before MEC can be applied at a practical level.

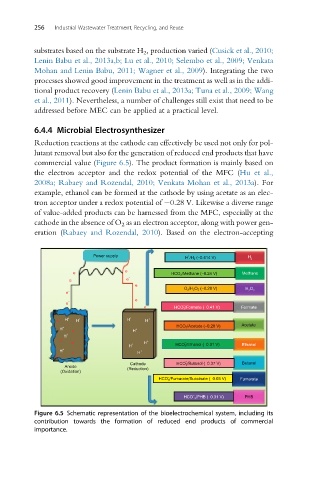

6.4.4 Microbial Electrosynthesizer

Reduction reactions at the cathode can effectively be used not only for pol-

lutant removal but also for the generation of reduced end products that have

commercial value (Figure 6.5). The product formation is mainly based on

the electron acceptor and the redox potential of the MFC (Hu et al.,

2008a; Rabaey and Rozendal, 2010; Venkata Mohan et al., 2013a). For

example, ethanol can be formed at the cathode by using acetate as an elec-

tron acceptor under a redox potential of 0.28 V. Likewise a diverse range

of value-added products can be harnessed from the MFC, especially at the

cathode in the absence of O 2 as an electron acceptor, along with power gen-

eration (Rabaey and Rozendal, 2010). Based on the electron-accepting

Power supply +

H /H 2 (-0.414 V) H 2

-

- e -

e HCO 3 /Methane (-0.24 V) Methane

- -

e e

e -

- O 2 /H 2 O 2 (-0.28 V) H O 2

2

e

-

- e

e

-

e - HCO 3 /Formate (-0.41 V) Formate

- H + + H + +

e H H -

+ HCO 3 /Acetate (-0.28 V) Acetate

H e - H +

+

H

-

e - +

-

e + H HCO 3 /Ethanol (-0.31 V) Ethanol

H

+

H - +

- e H

e

-

Cathode HCO 3 /Butanol (-0.37 V) Butanol

Anode

(Oxidation) (Reduction)

-

HCO 3 /Fumarate/Succinate (-0.03 V) Fumarate

-

HCO 3 /PHB (-0.31 V) PHB

Figure 6.5 Schematic representation of the bioelectrochemical system, including its

contribution towards the formation of reduced end products of commercial

importance.