Page 285 - Industrial Wastewater Treatment, Recycling and Reuse

P. 285

Reorienting Waste Remediation Towards Harnessing Bioenergy 259

CH O

3 CH CH O CH O CH CH O

2 3 3 2 3

n n

O O n

O O

PHB PHV PHBV

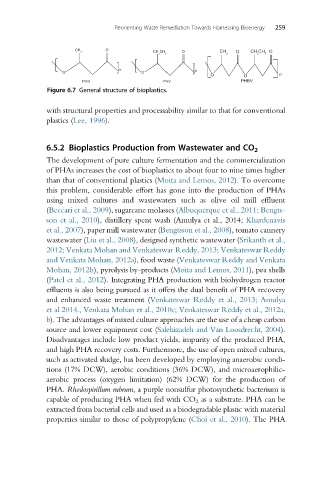

Figure 6.7 General structure of bioplastics.

with structural properties and processability similar to that for conventional

plastics (Lee, 1996).

6.5.2 Bioplastics Production from Wastewater and CO 2

The development of pure culture fermentation and the commercialization

of PHAs increases the cost of bioplastics to about four to nine times higher

than that of conventional plastics (Moita and Lemos, 2012). To overcome

this problem, considerable effort has gone into the production of PHAs

using mixed cultures and wastewaters such as olive oil mill effluent

(Beccari et al., 2009), sugarcane molasses (Albuquerque et al., 2011; Bengts-

son et al., 2010), distillery spent wash (Amulya et al., 2014; Khardenavis

et al., 2007), paper mill wastewater (Bengtsson et al., 2008), tomato cannery

wastewater (Liu et al., 2008), designed synthetic wastewater (Srikanth et al.,

2012; Venkata Mohan and Venkateswar Reddy, 2013; Venkateswar Reddy

and Venkata Mohan, 2012a), food waste (Venkateswar Reddy and Venkata

Mohan, 2012b), pyrolysis by-products (Moita and Lemos, 2011), pea shells

(Patel et al., 2012). Integrating PHA production with biohydrogen reactor

effluents is also being pursued as it offers the dual benefit of PHA recovery

and enhanced waste treatment (Venkateswar Reddy et al., 2013; Amulya

et al 2014., Venkata Mohan et al., 2010c; Venkateswar Reddy et al., 2012a,

b). The advantages of mixed culture approaches are the use of a cheap carbon

source and lower equipment cost (Salehizadeh and Van Loosdrecht, 2004).

Disadvantages include low product yields, impurity of the produced PHA,

and high PHA recovery costs. Furthermore, the use of open mixed cultures,

such as activated sludge, has been developed by employing anaerobic condi-

tions (17% DCW), aerobic conditions (36% DCW), and microaerophilic-

aerobic process (oxygen limitation) (62% DCW) for the production of

PHA. Rhodospirillum rubrum, a purple nonsulfur photosynthetic bacterium is

capable of producing PHA when fed with CO 2 as a substrate. PHA can be

extracted from bacterial cells and used as a biodegradable plastic with material

properties similar to those of polypropylene (Choi et al., 2010). The PHA