Page 340 - Industrial Wastewater Treatment, Recycling and Reuse

P. 340

312 Industrial Wastewater Treatment, Recycling, and Reuse

Lime coagulant

Secondary-wastewater made suitable for discharge (can have polyelectrolyte

significant modifications for cost reduction)

Balancing Aeration Secondary Intermediate

pond tank clarifier storage pond Clarifier

Primary-wastewater made

suitable for further treatment

Sludge

thickener

(chemical)

Bio sludge

Chemical sludge Filtration

Pressure sand

CaCO 2 sludge filters

CaCO 3

thickener

Cl 2

NH 3

Pressure

Ammonia Carbonation CaCO 3 Breakpoint

stripper tower clarifier sand chlorination

filters

Air CO 2

Overall

concern-

Multimedia Cartridge Reverse Permeate Recycle & total cost &

filters filters osmosis reservoir reuse sludge

disposal

Tertiary-wastewater made suitable

Na 2 HSO 3 Na 2 HSO 3 Reject for

disposal for recycle & reuse

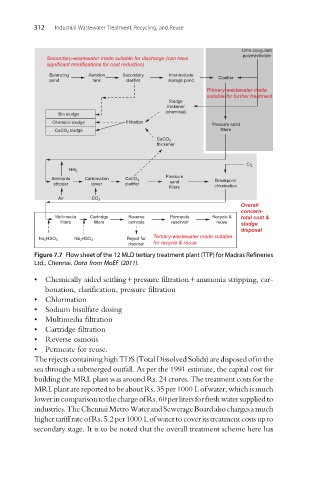

Figure 7.7 Flow sheet of the 12 MLD tertiary treatment plant (TTP) for Madras Refineries

Ltd., Chennai. Data from MoEF (2011).

• Chemically aided settling+pressure filtration+ammonia stripping, car-

bonation, clarification, pressure filtration

• Chlorination

• Sodium bisulfate dosing

• Multimedia filtration

• Cartridge filtration

• Reverse osmosis

• Permeate for reuse.

The rejects containing high TDS (Total DissolvedSolids) aredisposedof in the

sea through a submerged outfall. As per the 1991 estimate, the capital cost for

building the MRL plant was around Rs. 24 crores. The treatment costs for the

MRL plantare reportedto beabout Rs.35per 1000 L ofwater, which ismuch

lowerincomparisontothechargeofRs.60perlitersforfreshwatersuppliedto

industries.TheChennaiMetroWaterandSewerageBoardalsochargesamuch

higher tariffrate ofRs. 5.2 per1000 L of waterto coverits treatmentcosts up to

secondary stage. It is to be noted that the overall treatment scheme here has