Page 502 - Industrial Wastewater Treatment, Recycling and Reuse

P. 502

472 Industrial Wastewater Treatment, Recycling, and Reuse

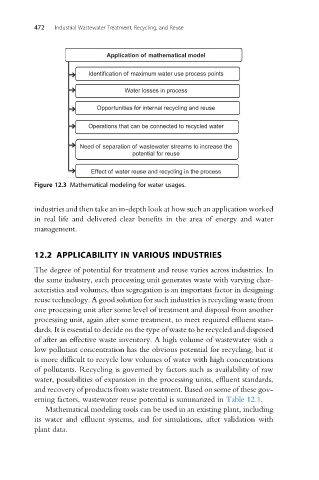

Application of mathematical model

Identification of maximum water use process points

Water losses in process

Opportunities for internal recycling and reuse

Operations that can be connected to recycled water

Need of separation of wastewater streams to increase the

potential for reuse

Effect of water reuse and recycling in the process

Figure 12.3 Mathematical modeling for water usages.

industries and then take an in-depth look at how such an application worked

in real life and delivered clear benefits in the area of energy and water

management.

12.2 APPLICABILITY IN VARIOUS INDUSTRIES

The degree of potential for treatment and reuse varies across industries. In

the same industry, each processing unit generates waste with varying char-

acteristics and volumes, thus segregation is an important factor in designing

reuse technology. A good solution for such industries is recycling waste from

one processing unit after some level of treatment and disposal from another

processing unit, again after some treatment, to meet required effluent stan-

dards. It is essential to decide on the type of waste to be recycled and disposed

of after an effective waste inventory. A high volume of wastewater with a

low pollutant concentration has the obvious potential for recycling, but it

is more difficult to recycle low volumes of water with high concentrations

of pollutants. Recycling is governed by factors such as availability of raw

water, possibilities of expansion in the processing units, effluent standards,

and recovery of products from waste treatment. Based on some of these gov-

erning factors, wastewater reuse potential is summarized in Table 12.1.

Mathematical modeling tools can be used in an existing plant, including

its water and effluent systems, and for simulations, after validation with

plant data.