Page 528 - Industrial Wastewater Treatment, Recycling and Reuse

P. 528

498 Industrial Wastewater Treatment, Recycling, and Reuse

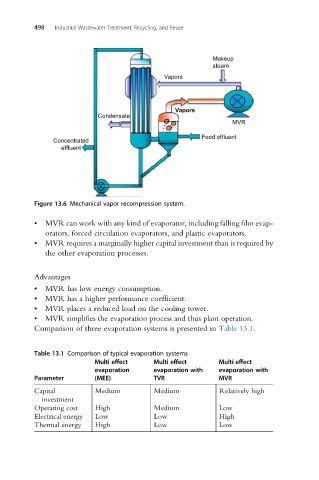

Makeup

steam

Vapors

Vapors

Condensate

MVR

Feed effluent

Concentrated

effluent

Figure 13.6 Mechanical vapor recompression system.

• MVR can work with any kind of evaporator, including falling film evap-

orators, forced circulation evaporators, and plastic evaporators.

• MVR requires a marginally higher capital investment than is required by

the other evaporation processes.

Advantages

• MVR has low energy consumption.

• MVR has a higher performance coefficient.

• MVR places a reduced load on the cooling tower.

• MVR simplifies the evaporation process and thus plant operation.

Comparison of three evaporation systems is presented in Table 13.1.

Table 13.1 Comparison of typical evaporation systems

Multi effect Multi effect Multi effect

evaporation evaporation with evaporation with

Parameter (MEE) TVR MVR

Capital Medium Medium Relatively high

investment

Operating cost High Medium Low

Electrical energy Low Low High

Thermal energy High Low Low