Page 542 - Industrial Wastewater Treatment, Recycling and Reuse

P. 542

512 Industrial Wastewater Treatment, Recycling, and Reuse

Recycle to

ETP

ETP

UF-RO

ML stream

Solvent

stripper

MEE

Ammoniacal

nitrogen stream

Ammonia

stripper

ATFD

Mixed salts

10% moisture

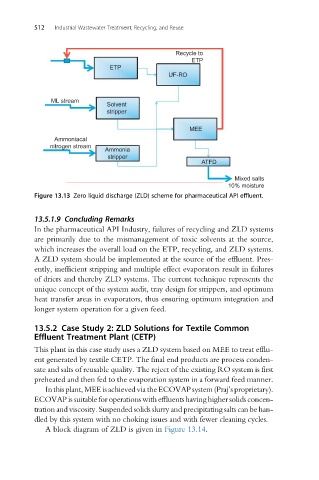

Figure 13.13 Zero liquid discharge (ZLD) scheme for pharmaceutical API effluent.

13.5.1.9 Concluding Remarks

In the pharmaceutical API Industry, failures of recycling and ZLD systems

are primarily due to the mismanagement of toxic solvents at the source,

which increases the overall load on the ETP, recycling, and ZLD systems.

A ZLD system should be implemented at the source of the effluent. Pres-

ently, inefficient stripping and multiple effect evaporators result in failures

of driers and thereby ZLD systems. The current technique represents the

unique concept of the system audit, tray design for strippers, and optimum

heat transfer areas in evaporators, thus ensuring optimum integration and

longer system operation for a given feed.

13.5.2 Case Study 2: ZLD Solutions for Textile Common

Effluent Treatment Plant (CETP)

This plant in this case study uses a ZLD system based on MEE to treat efflu-

ent generated by textile CETP. The final end products are process conden-

sate and salts of reusable quality. The reject of the existing RO system is first

preheated and then fed to the evaporation system in a forward feed manner.

In thisplant, MEE is achieved via theECOVAP system (Praj’s proprietary).

ECOVAP is suitable for operations with effluents havinghigher solids concen-

tration and viscosity. Suspended solids slurry and precipitating salts can be han-

dled by this system with no choking issues and with fewer cleaning cycles.

A block diagram of ZLD is given in Figure 13.14.