Page 539 - Industrial Wastewater Treatment, Recycling and Reuse

P. 539

Zero Liquid Discharge Solutions 509

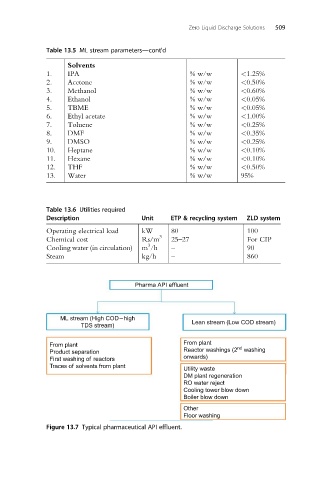

Table 13.5 ML stream parameters—cont'd

Solvents

1. IPA % w/w <1.25%

2. Acetone % w/w <0.50%

3. Methanol % w/w <0.60%

4. Ethanol % w/w <0.05%

5. TBME % w/w <0.05%

6. Ethyl acetate % w/w <1.00%

7. Toluene % w/w <0.25%

8. DMF % w/w <0.35%

9. DMSO % w/w <0.25%

10. Heptane % w/w <0.10%

11. Hexane % w/w <0.10%

12. THF % w/w <0.50%

13. Water % w/w 95%

Table 13.6 Utilities required

Description Unit ETP & recycling system ZLD system

Operating electrical load kW 80 100

Chemical cost Rs/m 3 25–27 For CIP

3

Cooling water (in circulation) m /h – 90

Steam kg/h – 860

Pharma API effluent

ML stream (High COD–high

TDS stream) Lean stream (Low COD stream)

From plant From plant nd

Product separation Reactor washings (2 washing

onwards)

First washing of reactors

Traces of solvents from plant

Utility waste

DM plant regeneration

RO water reject

Cooling tower blow down

Boiler blow down

Other

Floor washing

Figure 13.7 Typical pharmaceutical API effluent.