Page 543 - Industrial Wastewater Treatment, Recycling and Reuse

P. 543

Zero Liquid Discharge Solutions 513

Mother liquor

(from pusher

centrifuge)

Vapor liquid

Vapor liquid

separator-II

Steam separator-I

Forced Forced Surface Vent

circulation circulation condenser condenser

evaporator evaporator

effect-I effect-II

Vacuum

pump

Feed Feed

preheater preheater

Concentrated

product

Crystallize

Feed

Steam Process

Pusher

condensate condensate centrifuge

tank tank

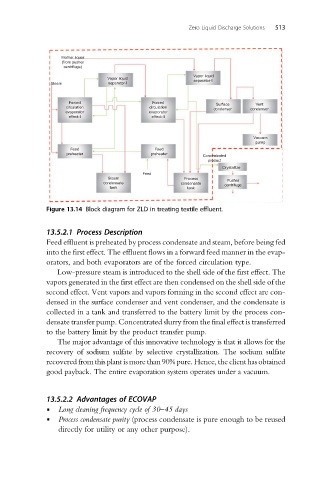

Figure 13.14 Block diagram for ZLD in treating textile effluent.

13.5.2.1 Process Description

Feed effluent is preheated by process condensate and steam, before being fed

into the first effect. The effluent flows in a forward feed manner in the evap-

orators, and both evaporators are of the forced circulation type.

Low-pressure steam is introduced to the shell side of the first effect. The

vapors generated in the first effect are then condensed on the shell side of the

second effect. Vent vapors and vapors forming in the second effect are con-

densed in the surface condenser and vent condenser, and the condensate is

collected in a tank and transferred to the battery limit by the process con-

densate transfer pump. Concentrated slurry from the final effect is transferred

to the battery limit by the product transfer pump.

The major advantage of this innovative technology is that it allows for the

recovery of sodium sulfate by selective crystallization. The sodium sulfate

recovered from this plant is more than 90% pure. Hence, the client has obtained

good payback. The entire evaporation system operates under a vacuum.

13.5.2.2 Advantages of ECOVAP

▪ Long cleaning frequency cycle of 30–45 days

▪ Process condensate purity (process condensate is pure enough to be reused

directly for utility or any other purpose).