Page 58 - Industrial Wastewater Treatment, Recycling and Reuse

P. 58

Industrial Wastewater Treatment, Recycling, and Reuse: An Overview 41

5. Oxidation ditch

– Similar to extended aeration, except the aeration is done by brush-

type aerators, thus reducing electricity usage.

6. High rate

– Short detention time and high F/M ratio in aerator to maintain culture

in the log-growth phase.

7. Extended aeration

– Long detention time and low F/M ratio in aerator to maintain culture

in the endogenous phase.

8. Sequencing batch reactor

– Only one reactor for both aeration and sludge settlement—lower

capital cost. A special form of ASP that operates in batch mode with

sequencing.

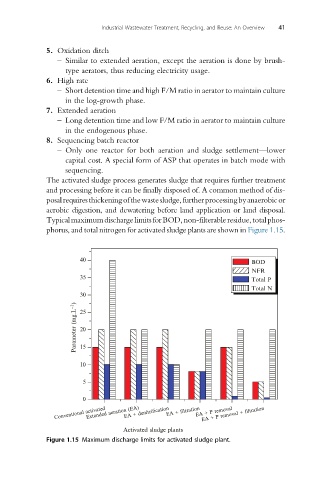

The activated sludge process generates sludge that requires further treatment

and processing before it can be finally disposed of. A common method of dis-

posalrequiresthickeningofthewastesludge,furtherprocessingbyanaerobicor

aerobic digestion, and dewatering before land application or land disposal.

TypicalmaximumdischargelimitsforBOD,non-filterableresidue,totalphos-

phorus, and total nitrogen for activated sludge plants are shown in Figure 1.15.

40

BOD

NFR

35 Total P

Total N

30

Parameter (mg.L –1 ) 25

20

15

10

5

0

Extended aeration (EA)

Conventional activated EA + denitrification EA + filtration EA + P removal

EA + P removal + filtration

Activated sludge plants

Figure 1.15 Maximum discharge limits for activated sludge plant.