Page 279 - Injection Molding Advanced Troubleshooting Guide

P. 279

28.3 High Fill Pressure Troubleshooting 271

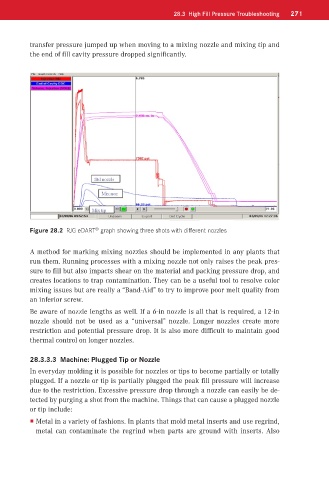

transfer pressure jumped up when moving to a mixing nozzle and mixing tip and

the end of fill cavity pressure dropped significantly.

Figure 28.2 RJG eDART graph showing three shots with different nozzles

®

A method for marking mixing nozzles should be implemented in any plants that

run them. Running processes with a mixing nozzle not only raises the peak pres-

sure to fill but also impacts shear on the material and packing pressure drop, and

creates locations to trap contamination. They can be a useful tool to resolve color

mixing issues but are really a “Band-Aid” to try to improve poor melt quality from

an inferior screw.

Be aware of nozzle lengths as well. If a 6-in nozzle is all that is required, a 12-in

nozzle should not be used as a “universal” nozzle. Longer nozzles create more

restriction and potential pressure drop. It is also more difficult to maintain good

thermal control on longer nozzles.

28.3.3.3 Machine: Plugged Tip or Nozzle

In everyday molding it is possible for nozzles or tips to become partially or totally

plugged. If a nozzle or tip is partially plugged the peak fill pressure will increase

due to the restriction. Excessive pressure drop through a nozzle can easily be de-

tected by purging a shot from the machine. Things that can cause a plugged nozzle

or tip include:

Metal in a variety of fashions. In plants that mold metal inserts and use regrind,

metal can contaminate the regrind when parts are ground with inserts. Also