Page 281 - Injection Molding Advanced Troubleshooting Guide

P. 281

28.3 High Fill Pressure Troubleshooting 273

Case Study: Machine Accuracy

In this example a molding machine had a deviation of 200 psi hydraulic

pressure from the set point. In this particular case the set point on the

controller did not match the actual pressure displayed on the controller, nor

did it match the hydraulic pressure gauge. An RJG eDART process monitoring

system was connected to the machine to provide an additional confirmation

and showed that the machine was in fact running 200 psi low on the

hydraulic pressure. A handheld pressure gauge can be plugged into the test

ports on the machine to verify pressure if a process monitoring system is

unavailable.

This pressure inaccuracy explained why mold ABC never ran well in this ma-

chine! The process was not matching the documented and validated setup.

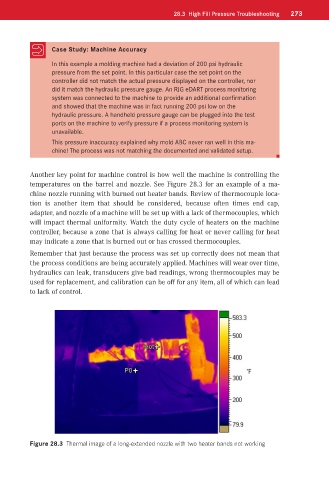

Another key point for machine control is how well the machine is controlling the

temperatures on the barrel and nozzle. See Figure 28.3 for an example of a ma-

chine nozzle running with burned out heater bands. Review of thermocouple loca-

tion is another item that should be considered, because often times end cap,

adapter, and nozzle of a machine will be set up with a lack of thermocouples, which

will impact thermal uniformity. Watch the duty cycle of heaters on the machine

controller, because a zone that is always calling for heat or never calling for heat

may indicate a zone that is burned out or has crossed thermocouples.

Remember that just because the process was set up correctly does not mean that

the process conditions are being accurately applied. Machines will wear over time,

hydraulics can leak, transducers give bad readings, wrong thermocouples may be

used for replacement, and calibration can be off for any item, all of which can lead

to lack of control.

Figure 28.3 Thermal image of a long-extended nozzle with two heater bands not working