Page 285 - Injection Molding Advanced Troubleshooting Guide

P. 285

278 29 Flaking

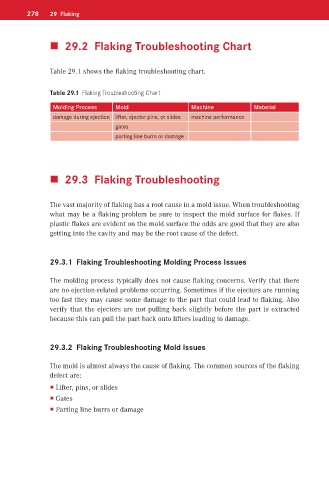

29.2 Flaking Troubleshooting Chart

Table 29.1 shows the flaking troubleshooting chart.

Table 29.1 Flaking Troubleshooting Chart

Molding Process Mold Machine Material

damage during ejection lifter, ejector pins, or slides machine performance

gates

parting line burrs or damage

29.3 Flaking Troubleshooting

The vast majority of flaking has a root cause in a mold issue. When troubleshooting

what may be a flaking problem be sure to inspect the mold surface for flakes. If

plastic flakes are evident on the mold surface the odds are good that they are also

getting into the cavity and may be the root cause of the defect.

29.3.1 Flaking Troubleshooting Molding Process Issues

The molding process typically does not cause flaking concerns. Verify that there

are no ejection-related problems occurring. Sometimes if the ejectors are running

too fast they may cause some damage to the part that could lead to flaking. Also

verify that the ejectors are not pulling back slightly before the part is extracted

because this can pull the part back onto lifters leading to damage.

29.3.2 Flaking Troubleshooting Mold Issues

The mold is almost always the cause of flaking. The common sources of the flaking

defect are:

Lifter, pins, or slides

Gates

Parting line burrs or damage