Page 290 - Injection Molding Advanced Troubleshooting Guide

P. 290

30.3 Flash Troubleshooting 283

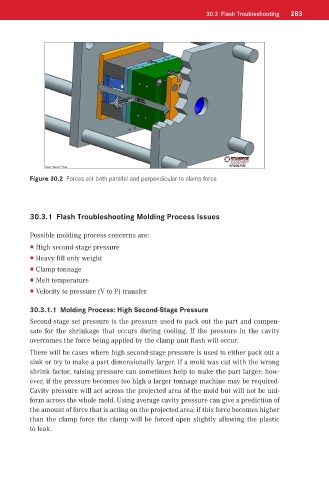

Figure 30.2 Forces act both parallel and perpendicular to clamp force

30.3.1 Flash Troubleshooting Molding Process Issues

Possible molding process concerns are:

High second-stage pressure

Heavy fill only weight

Clamp tonnage

Melt temperature

Velocity to pressure (V to P) transfer

30.3.1.1 Molding Process: High Second-Stage Pressure

Second-stage set pressure is the pressure used to pack out the part and compen-

sate for the shrinkage that occurs during cooling. If the pressure in the cavity

overcomes the force being applied by the clamp unit flash will occur.

There will be cases where high second-stage pressure is used to either pack out a

sink or try to make a part dimensionally larger. If a mold was cut with the wrong

shrink factor, raising pressure can sometimes help to make the part larger; how-

ever, if the pressure becomes too high a larger tonnage machine may be required.

Cavity pressure will act across the projected area of the mold but will not be uni-

form across the whole mold. Using average cavity pressure can give a prediction of

the amount of force that is acting on the projected area; if this force becomes higher

than the clamp force the clamp will be forced open slightly allowing the plastic

to leak.