Page 292 - Injection Molding Advanced Troubleshooting Guide

P. 292

30.3 Flash Troubleshooting 285

30.3.1.3 Molding Process: Clamp Tonnage

The clamp unit of the molding machine must hold the mold shut during the mold-

ing process. If the clamp force is too low then the cavity pressure will cause the

mold to blow open allowing plastic to escape as flash.

Verify that the die height on a toggle machine is locking up tight. Many new

presses have automatic die height settings that make this simple. On older ma-

chines the die height will need to be manually adjusted to ensure that the clamp is

tight. On machines that have adjustable clamp tonnage settings verify that the

tonnage is set to the appropriate level. A 500-ton press with the clamp tonnage set

at 400 tons is no better than a 400-ton press. If you need the 500 tons make sure

that the machine is set appropriately.

To determine if a mold is being forced open during the process use either a dial

indicator or a 0–10-V device connected to a process monitoring system. The mea-

surement device should be mounted across the parting line of the mold and zeroed

out. Run the process on cycle and watch for movement.

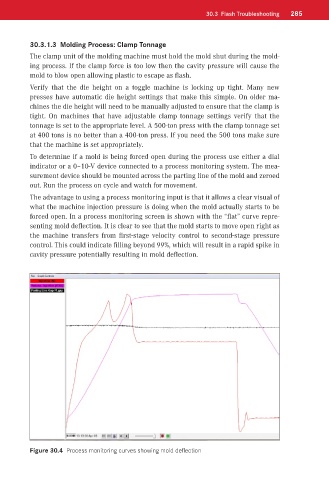

The advantage to using a process monitoring input is that it allows a clear visual of

what the machine injection pressure is doing when the mold actually starts to be

forced open. In a process monitoring screen is shown with the “flat” curve repre-

senting mold deflection. It is clear to see that the mold starts to move open right as

the machine transfers from first-stage velocity control to second-stage pressure

control. This could indicate filling beyond 99%, which will result in a rapid spike in

cavity pressure potentially resulting in mold deflection.

Figure 30.4 Process monitoring curves showing mold deflection