Page 289 - Injection Molding Advanced Troubleshooting Guide

P. 289

282 30 Flash

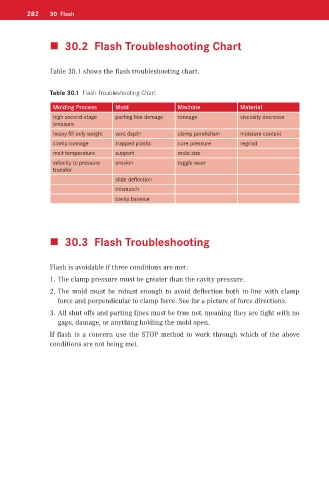

30.2 Flash Troubleshooting Chart

Table 30.1 shows the flash troubleshooting chart.

Table 30.1 Flash Troubleshooting Chart

Molding Process Mold Machine Material

high second-stage parting line damage tonnage viscosity decrease

pressure

heavy fill only weight vent depth clamp parallelism moisture content

clamp tonnage trapped plastic core pressure regrind

melt temperature support mold size

velocity to pressure erosion toggle wear

transfer

slide deflection

mismatch

cavity balance

30.3 Flash Troubleshooting

Flash is avoidable if three conditions are met:

1. The clamp pressure must be greater than the cavity pressure.

2. The mold must be robust enough to avoid deflection both in-line with clamp

force and perpendicular to clamp force. See for a picture of force directions.

3. All shut offs and parting lines must be true net, meaning they are tight with no

gaps, damage, or anything holding the mold open.

If flash is a concern use the STOP method to work through which of the above

conditions are not being met.