Page 30 - Injection Molding Advanced Troubleshooting Guide

P. 30

1.4 Troubleshooting Methodology 11

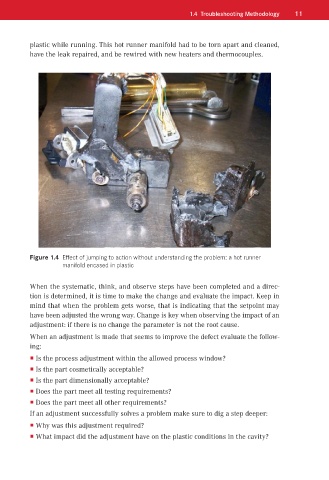

plastic while running. This hot runner manifold had to be torn apart and cleaned,

have the leak repaired, and be rewired with new heaters and thermocouples.

Figure 1.4 Effect of jumping to action without understanding the problem: a hot runner

manifold encased in plastic

When the systematic, think, and observe steps have been completed and a direc-

tion is determined, it is time to make the change and evaluate the impact. Keep in

mind that when the problem gets worse, that is indicating that the setpoint may

have been adjusted the wrong way. Change is key when observing the impact of an

adjustment: if there is no change the parameter is not the root cause.

When an adjustment is made that seems to improve the defect evaluate the follow-

ing:

Is the process adjustment within the allowed process window?

Is the part cosmetically acceptable?

Is the part dimensionally acceptable?

Does the part meet all testing requirements?

Does the part meet all other requirements?

If an adjustment successfully solves a problem make sure to dig a step deeper:

Why was this adjustment required?

What impact did the adjustment have on the plastic conditions in the cavity?